Blog

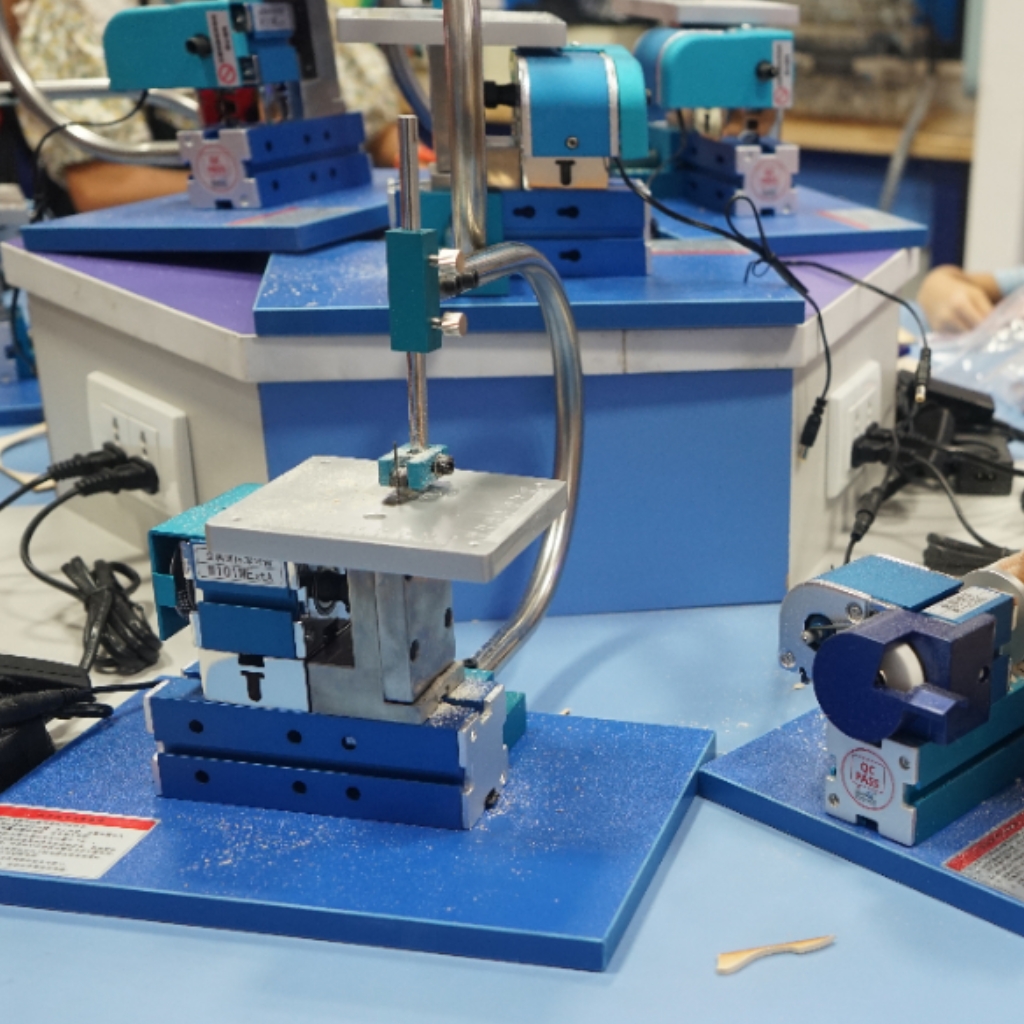

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Oct 20, 2025

Oct 20, 2025

849

849

If you've ever browsed for a benchtop lathe, whether you're a seasoned machinist or a hobbyist setting up your first workshop, you've likely encountered the term "hollow spindle." It might seem like a minor specification, but this feature is a cornerstone of modern lathe design, especially in the compact, powerful machines offered by brands like Xendoll. But why is this hollow design so prevalent and important? Simply put, a hollow spindle is not an empty space; it's a critical passageway that dramatically enhances a lathe's versatility, capability, and efficiency. By allowing workpieces and accessories to pass directly through the headstock, it unlocks a wider range of projects and streamlines the machining process.

Let's break down the key reasons why this design is so beneficial.

The most significant advantage of a hollow spindle is its ability to accommodate workpieces that are longer than the lathe bed itself. Without this feature, the maximum length of a workpiece you can turn is limited by the distance between the headstock and the tailstock.

How it Works: With a hollow spindle, a long bar of material (such as steel, aluminum, or brass) can be fed through the spindle bore. One end is secured in a chuck, while the excess length protrudes out the back of the headstock. As you turn down the exposed section, you can simply pull more material through the spindle, allowing you to create multiple parts from a single long bar or work on a long shaft without interruption.

Practical Application: This is indispensable for producing items like threaded rods, automotive axles, tool handles, or any series of small, identical components. For mechanical dealers and serious machining enthusiasts, this capability is a massive time-saver, eliminating the need to cut stock to a precise length before starting each small part.

Machining is a messy business, generating heat and a continuous flow of metal chips. A hollow spindle plays a crucial role in managing this by-product, especially in production or high-volume hobbyist environments.

How it Works: On larger industrial lathes, high-pressure coolant systems are often used. The hollow spindle allows this coolant to be delivered directly through the center of the spindle and onto the cutting tool, ensuring optimal heat reduction and lubrication right at the point of contact. Furthermore, the through-hole allows chips to be evacuated out the back of the machine, preventing a dangerous and messy buildup around the workpiece and chuck.

Practical Application: While smaller mini-lathes may not have pressurized through-spindle coolant, the hollow design still aids in chip clearance. For educational equipment dealers, this feature demonstrates professional-grade machining principles to students in a safe and manageable format.

It might seem counterintuitive, but a properly engineered hollow spindle can be more rigid and produce less vibration than a solid one of the same outer diameter.

How it Works: The physics behind this is similar to why an I-beam is used in construction. Material removed from the center of a cylinder does little to reduce its bending resistance but significantly lowers its weight. A lighter spindle, driven by the same motor, has lower rotational inertia, allowing for quicker start and stop times. More importantly, the remaining mass is distributed at the outer diameter, where it most effectively resists bending forces from the cutting tool, leading to a more stable and chatter-free cut.

Practical Application: This results in a better surface finish on your parts and allows for more aggressive cutting passes. For users of Xendoll's mini lathes and milling machines, this means professional-level precision even on a compact machine.

The hollow spindle is the gateway to more advanced workholding options and even basic automation.

How it Works: The through-hole allows for the use of collets, like 5C or R8, which are passed through the spindle and secured with a drawtube. Collets provide exceptional accuracy and grip for round stock and are essential for precision work. Furthermore, the hollow design is a prerequisite for integrating bar feeders—automated systems that push new material into the work area once a part is completed, enabling small-scale, unattended production runs.

Practical Application: For a machining enthusiast looking to upgrade their capabilities, the presence of a hollow spindle means their Xendoll lathe can grow with them. They can invest in a collet system later to achieve new levels of precision, a feature highly valued by model engineers and instrument makers.

In summary, the hollow spindle is far from a simple hole; it is a thoughtfully engineered feature that defines a lathe's potential. From enabling the machining of long, slender workpieces and improving chip management to enhancing rigidity and opening the door to advanced workholding, its benefits are multifaceted. When you choose a lathe from Xendoll Tools, you are not just getting a machine; you are investing in a platform designed for versatility, precision, and growth. Whether you are a distributor supplying workshops or an educator training the next generation of machinists, understanding and promoting the value of the hollow spindle will highlight the sophisticated engineering packed into our modern mini-lathes.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options