In the world of mechanical engineering and manufacturing, few machines are as fundamental and iconic as the lathe. Often hailed as the "mother of all machine tools," the lathe is the cornerstone upon which modern industry was built. But what exactly is a lathe machine, and why does it remain so critically important? In simple terms, a lathe is a machine tool that rotates a workpiece on its axis to perform various operations like cutting, sanding, knurling, drilling, or deformation with tools that are applied to the workpiece to create an object with symmetry about an axis of rotation. For mechanical engineering students, machining enthusiasts, and industrial professionals, mastering the lathe is a essential skill. At Xendoll Tools, we understand this deeply, which is why we engineer our premium mini lathes to deliver this foundational power with precision and reliability, right to your workshop.

The Core Principle: How a Lathe Works (Support)

The fundamental principle of every lathe, from massive industrial models to the compact Xendoll mini lathe, is relatively straightforward: the workpiece is rotated, and a stationary cutting tool is carefully moved against it to remove material. This process is known as "turning." The primary motion is provided by the rotating spindle (holding the workpiece), while the secondary, feed motion is provided by the tool moving along predefined paths. This allows for the creation of precise cylindrical or conical shapes. Operations like facing (creating a flat surface at the end of a cylinder), tapering, and threading are all achieved by controlling the path and angle of the cutting tool relative to the spinning workpiece.

Key Components of a Standard Lathe Machine (Support)

To fully appreciate its functionality, let's break down the key components of a standard engine lathe:

Bed: The robust, foundational base of the machine, often made of cast iron. It supports all other major components and ensures rigidity and vibration damping.

Headstock: Located at the left end of the bed, the headstock houses the main spindle, the chuck (which holds the workpiece), and the driving motor and gearing system responsible for providing various spindle speeds.

Tailstock: Situated on the opposite end of the headstock, the tailstock is movable and used to support the end of long workpieces with a center. It can also hold tools for drilling or reaming.

Carriage: This is the assembly that moves the cutting tool along the bed. It consists of several parts:

Saddle: Moves along the bed's guideways.

Cross Slide: Moves the tool perpendicular to the axis of the workpiece.

Compound Rest: Supports the tool post and can be swiveled for angled cuts.

Tool Post: Holds the cutting tool securely in place.

Lead Screw and Feed Rod: These precision screws automate the movement of the carriage for threading and providing consistent feed rates.

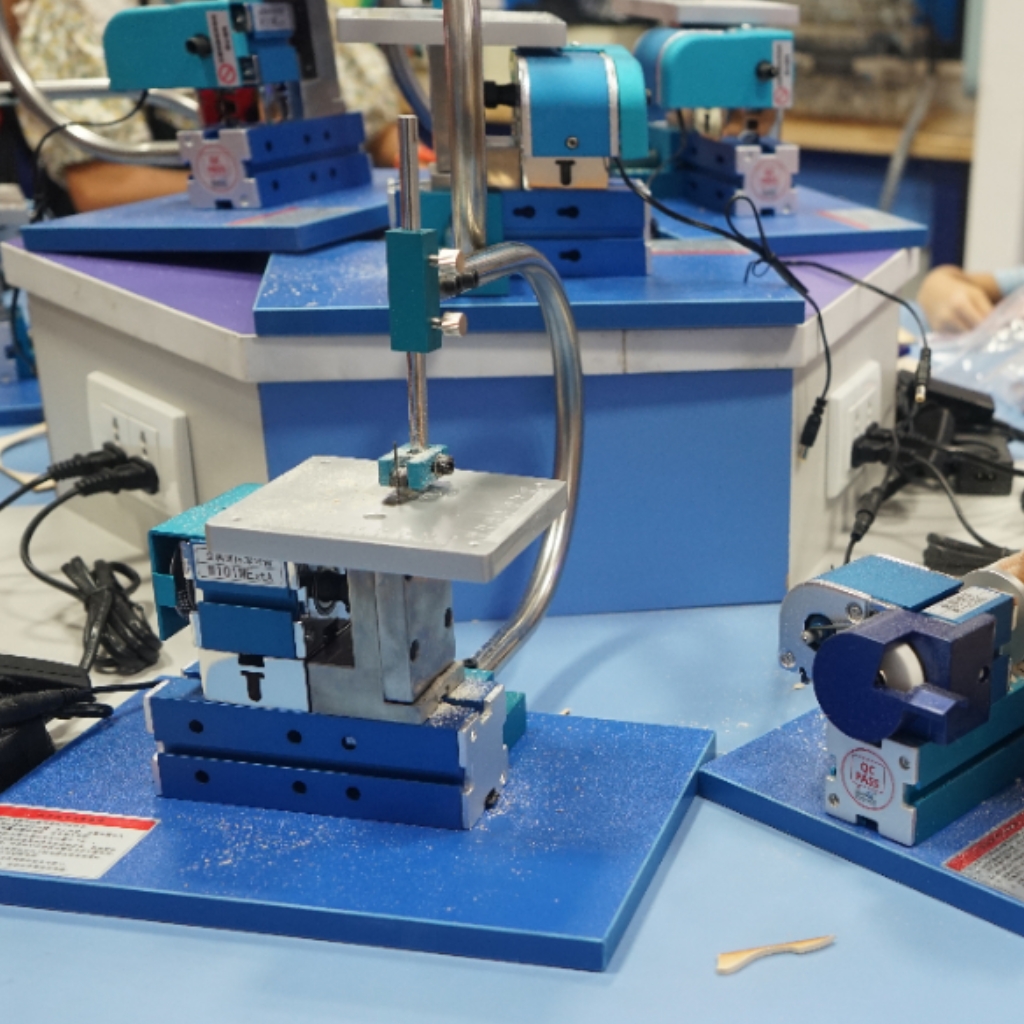

Modern iterations, like the Xendoll mini lathe for hobbyists, integrate these same core components in a compact, user-friendly design, often with digital readouts and variable speed control for enhanced precision.

Common Operations Performed on a Lathe (Support)

The versatility of a lathe machine is demonstrated by the wide range of operations it can perform:

Turning: The basic operation of removing material from the outside diameter of a workpiece to create a smooth cylindrical surface.

Facing: Machining the end of a workpiece flat and perpendicular to its axis.

Parting (or Cutting Off): The process of cutting a workpiece into two separate pieces.

Drilling: By holding a drill bit in the tailstock, a lathe can accurately drill axial holes in the center of a workpiece.

Boring: Enlarging or refining an existing hole to a precise diameter.

Knurling: Pressing a patterned tool against the rotating workpiece to create a rough, grip-enhancing surface.

Threading: Cutting helical grooves (internal or external threads) onto a workpiece.

Applications: From Massive Industry to the Home Workshop (Support)

The application of lathes is vast and varied, underscoring their indispensability.

Industrial Manufacturing: Used for producing shafts, gears, pulleys, bolts, and a myriad of other precision components for automotive, aerospace, and machinery industries.

Education and Training: Technical schools and universities worldwide use lathes, including durable educational mini lathes, to teach students the principles of machining, measurement, and manufacturing.

Model Engineering and Hobbyist Projects: This is where Xendoll Tools excels. Our machines are perfect for enthusiasts who build model steam engines, custom automotive parts, precision tools, clocks, and intricate wood or metal artwork.

Safety First: Essential Practices for Lathe Operation (Support)

No discussion about lathes is complete without emphasizing safety. Key rules include:

Always wear safety glasses.

Never wear loose clothing, gloves, or jewelry that could get caught.

Ensure the workpiece and tool are secured tightly.

Stop the machine before making adjustments or measurements.

Understand the machine's emergency stop function.

Our Xendoll mini lathes are designed with user safety in mind, featuring stable construction and clear operational guidelines.

Conclusion: The Indispensable Tool for Creation (Total)

In conclusion, the lathe machine is far more than just a piece of equipment; it is a fundamental tool of creation in mechanical engineering. Its ability to shape raw materials into precise, functional, and symmetrical parts makes it irreplaceable in industries, educational institutions, and the workshops of dedicated hobbyists. From crafting massive industrial components to delicate model parts, the lathe's principle remains timeless. At Xendoll Tools, we are proud to support this spirit of creation and precision engineering. We invite you to explore our range of high-quality, reliable mini lathes and discover how our tools can empower your next project. Visit our website at xendolltools.com to find the perfect machine for your workshop needs.

Oct 23, 2025

Oct 23, 2025

706

706

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options