Blog

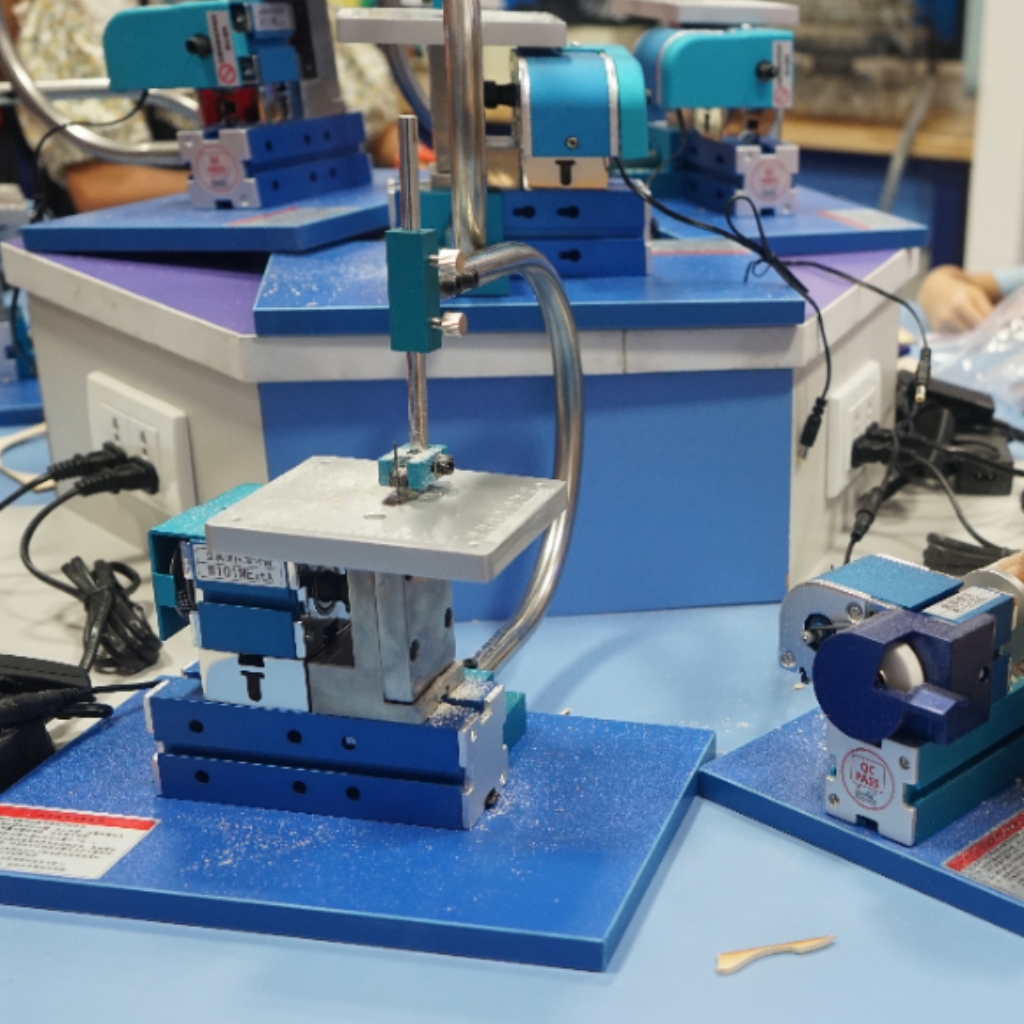

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Oct 17, 2025

Oct 17, 2025

601

601

For machining enthusiasts, educational institutions, and industrial suppliers, the lathe machine is the undisputed cornerstone of precision workshop. It's a versatile tool capable of transforming raw material into intricate, functional, and beautiful objects. But for those new to the craft or looking to expand their product offerings, a common question arises: What are the tangible outputs of this powerful machine?

Understanding the sample products of a lathe is crucial. It not only showcases the machine's capabilities but also inspires new projects and business opportunities. From essential mechanical components to bespoke artistic creations, the lathe's potential is nearly limitless. This article will explore a range of sample products, demonstrating why a high-quality mini lathe, like those from Xendoll, is an invaluable asset for creators and dealers alike.

At its core, a lathe is designed for producing rotationally symmetric parts. Many of its most common products are fundamental building blocks in mechanics, engineering, and DIY projects.

Shafts and Axles: These are among the most straightforward yet vital products. A lathe is used to turn a piece of metal or wood rod to a specific diameter, ensuring it is perfectly round and smooth. Examples include:

Engine Crankshafts: While complex ones require advanced machining, simple model engine shafts are a perfect project for mini lathes.

Rollers and Pulleys: Used in conveyor systems, 3D printers, and various drive mechanisms.

Axles for Model Cars and Robotics: Precision-made axles ensure smooth movement and reduce friction.

Busings and Bearings: These components are used to reduce friction between two rotating parts. A lathe can create custom-sized bushings that are not readily available off-the-shelf. Machining a bronze bushing to exact specifications is a classic lathe operation that highlights precision and fit.

Bolts and Nuts: For the true machinist, creating a custom bolt or a specialized nut from a hex bar of steel is a rite of passage. This process involves threading—a fundamental lathe operation—demonstrating complete control over fastener creation, which is invaluable for custom machinery repairs or prototypes.

Beyond basic components, the lathe excels in producing specialized tools and artistic pieces, showcasing its adaptability.

Tool Handles: One of the most popular and satisfying projects for beginners and pros alike is turning custom handles. Using materials like wood, acrylic, or aluminum, a lathe can create ergonomic and beautiful handles for:

Hammers, Files, and Screwdrivers

Kitchen Knives and Custom Cutlery

Pen Turning: This is a flagship project for the mini-lathe community. Crafting elegant pens from exotic woods, resins, or metals is a perfect application that yields a functional, marketable product.

Musical Instrument Components: The precision of a lathe is essential in lutherie (instrument making). It is used to create:

Woodwind Instrument Parts: Such as the bodies of recorders or clarinets.

Guitar Parts: Including tuning pegs, knobs, and even the occasional solid electric guitar body.

Drum Hardware: Precision-made lugs and tension rods.

Decorative and Household Items: This is where creativity truly shines. A lathe can produce stunning decorative objects that blend form and function.

Candlesticks and Vases: Timeless projects that involve complex shapes and elegant profiles.

Chess Pieces: Turning a full set of chess pieces is a master-level project that demonstrates skill in creating consistent, detailed forms.

Bowls and Plates: From small, delicate wooden bowls to larger salad bowls, this is a classic woodturning application that highlights the lathe's ability to hollow out material.

As we have seen, the sample products of a lathe machine range from the critically functional—shafts, bolts, and bushings—to the artistically exquisite—pens, instruments, and decorative art. This versatility is what makes the lathe a central tool in workshops across the globe, serving the needs of mechanical engineers, vocational trainers, and hobbyists.

The key to successfully creating these diverse products lies not just in skill, but in the quality and precision of the machine itself. A robust, accurate, and user-friendly mini lathe provides the stable foundation required for everything from roughing out a steel axle to applying the final polish on a delicate pen.

For overseas machinery dealers and educational equipment distributors, stocking reliable mini lathes means providing your customers with the tool they need to unlock this entire world of creation. For the machining enthusiast, investing in a high-performance lathe from a trusted brand like Xendoll is the first step towards mastering the craft and bringing your innovative ideas to life.

Discover the precision and power that drives innovation. Explore our range of premium mini lathes and accessories at xendolltools.com and turn your potential into reality.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options