In the world of machining and fabrication, the term "lathe" encompasses a wide range of machines, from massive industrial CNC lathes to small, versatile bench-top models. Among these, the speed lathe holds a unique and fundamental place. But what exactly is a speed lathe? In essence, a speed lathe is a simple, manually operated lathe characterized by its high rotational speeds and absence of a power-fed carriage. It is one of the most basic and oldest types of lathes, yet it remains an indispensable tool for specific tasks in workshops, educational institutions, and industries worldwide. This article will demystify the speed lathe, exploring its core components, typical applications, and the distinct advantages it offers to machining enthusiasts, educators, and professionals.

The Core Components and Simplicity of a Speed Lathe

A speed lathe's design is defined by its simplicity. Unlike more complex engine lathes or CNC lathes, it lacks complicated gearboxes, lead screws, or automatic feed mechanisms. Its primary components are few but crucial:

Bed: The solid foundation of the lathe, usually a rigid horizontal beam, which supports all other components.

Headstock: Located at one end of the bed, the headstock houses the main spindle. The key feature of a speed lathe is that the spindle is connected directly to a motor, often via a belt-drive system, allowing it to achieve very high rotational speeds (RPM).

Tailstock: Situated at the opposite end of the headstock, the tailstock is movable and can be locked in place. It holds a center (like a live or dead center) to support the free end of a workpiece, providing stability during operations.

Tool Rest: This is perhaps the most distinctive feature. Instead of a power-fed compound rest, a speed lathe has a simple, adjustable tool rest. The operator manually holds the cutting tool (such as a chisel or gouge) against this rest to perform operations.

This minimalist design is its greatest strength. Without complex systems, it is easy to set up, operate, and maintain, making it an excellent tool for beginners and a quick-solution machine for experts.

Typical Applications: Where the Speed Lathe Excels

The speed lathe is not designed for heavy-duty metal removal or intricate threading. Instead, its high-speed, manual control makes it perfect for precision finishing and delicate work. Common applications include:

Woodturning: This is one of its most popular uses. The high RPM is ideal for shaping and sanding wood. Artisans and hobbyists use it to create spindles, pens, bowls, and other artistic pieces.

Polishing and Buffing: The smooth, high-speed rotation is perfect for polishing metal, plastic, or wooden parts to a high-gloss finish. By holding polishing wheels or buffing compounds against the spinning workpiece, a flawless surface can be achieved efficiently.

Spinning (Metal Spinning): In this specialized process, a disc of metal (like aluminum or copper) is pressed against a rotating form (mandrel) with manual tools. The speed lathe's control and power are essential for forming shapes like decorative items, lamp shades, or musical instrument components.

Centering and Light Machining: It is often used for light facing, chamfering edges, or creating center holes in workpieces before they are transferred to a more powerful lathe.

The Advantages of Choosing a Speed Lathe

Why would a machinist, educator, or hobbyist choose a speed lathe over a more feature-rich model? The benefits are clear:

Affordability: Due to its simple construction, a speed lathe is significantly more affordable than an engine or CNC lathe, offering a low barrier to entry.

Ease of Use: The learning curve is gentle. It teaches the fundamental principles of turning without the intimidation of complex controls, making it the perfect training tool in educational settings for vocational schools and university workshops.

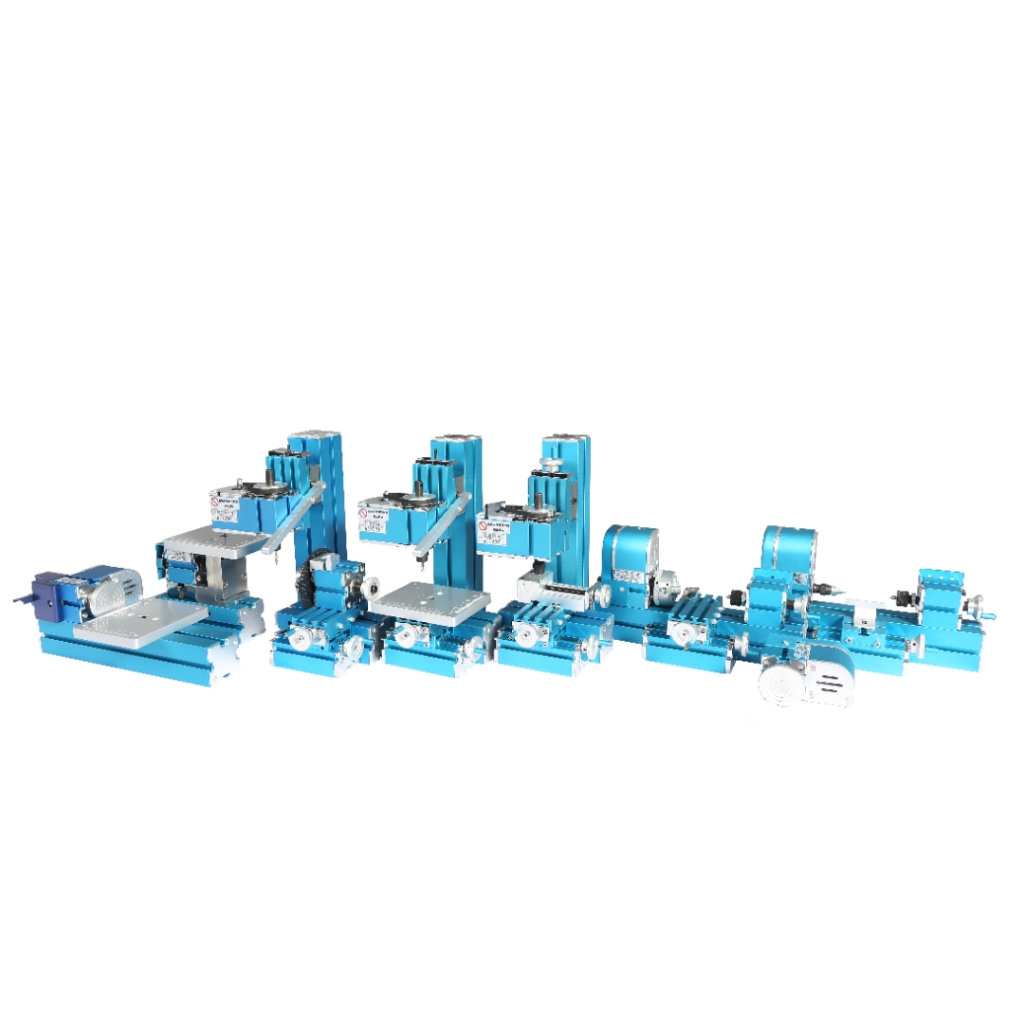

Space Efficiency: Often designed as bench-top models, speed lathes like those from Xendoll Tools have a small footprint, fitting perfectly into home workshops, garages, or crowded classrooms.

Versatility for Specific Tasks: For the tasks it is designed for—polishing, woodturning, spinning—it is often faster and more effective than a larger, slower machine.

Conclusion: The Enduring Value of the Speed Lathe

In summary, a speed lathe is a fundamental machining tool defined by its high rotational speed, manual operation, and straightforward design. While it may not possess the brute power or automated capabilities of its larger cousins, its value lies in its specialization for precision finishing, woodworking, and polishing. For mechanical processing enthusiasts, it offers an accessible gateway into the world of turning. For educational equipment dealers, it represents an essential, student-friendly training apparatus. And for overseas machinery distributors, it is a reliable, in-demand product for a wide market of light industrial and artistic users. By understanding its purpose and strengths, it becomes clear that the humble speed lathe is not an obsolete machine but a timeless and vital tool for creators and craftsmen everywhere.

Explore high-quality, precision-engineered speed lathes and mini machine tools designed for professionals and hobbyists at Xendoll Tools. Visit xendolltools.com to find the perfect equipment for your workshop.

Sep 26, 2025

Sep 26, 2025

878

878

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options