Blog

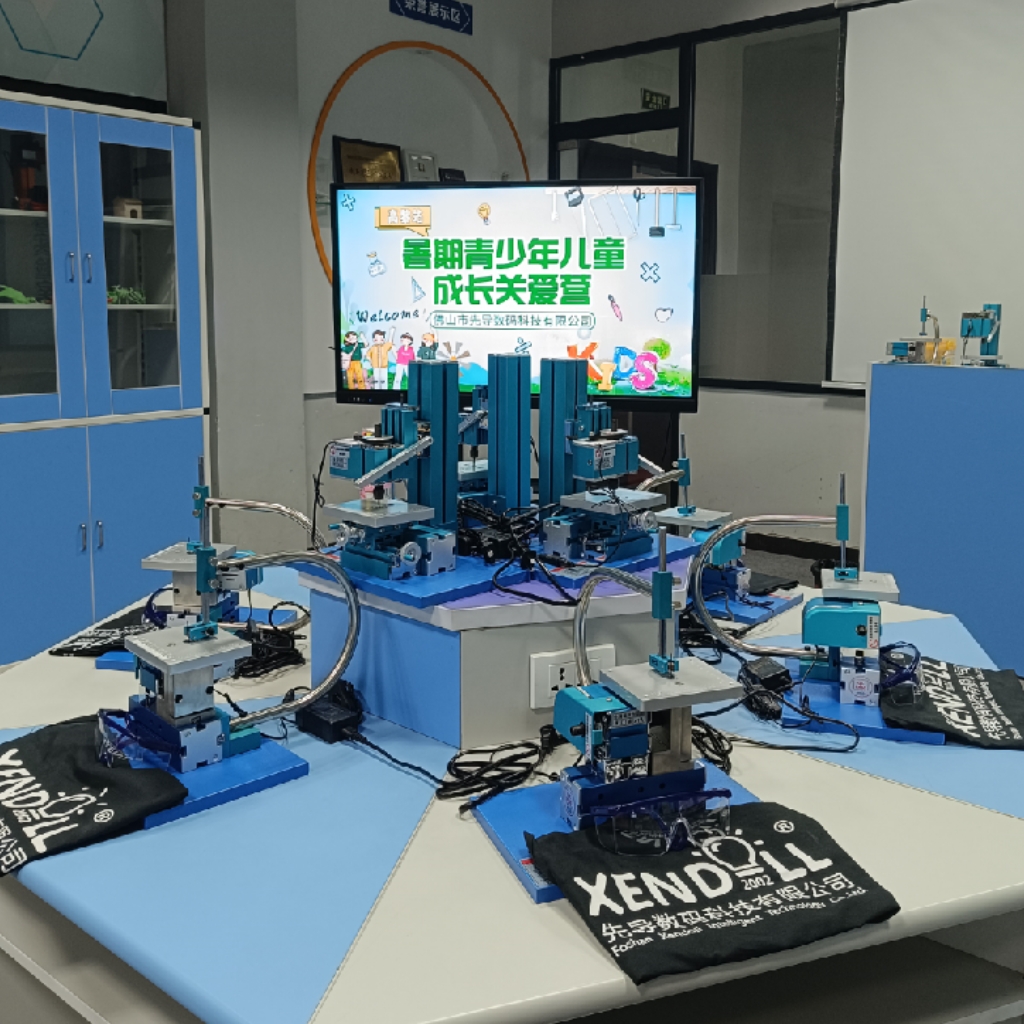

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Sep 23, 2025

Sep 23, 2025

828

828

Introduction

In the world of metalworking, whether you're a professional machinist, an educational instructor, or a dedicated hobbyist, efficiency and accuracy are paramount. The right equipment doesn't just complete a task; it elevates the entire project, ensuring flawless results and a smoother workflow. Meeting this need for reliability and performance is the Xendoll Metal Drilling Machine W105M. Engineered as an ideal choice for professionals, this drill press is designed to tackle various metal materials with ease. Its combination of robust power and exceptional precision makes it a standout tool for any workshop aiming to enhance productivity and achieve perfect results on every drilling job. This article will delve into the key features that make the Xendoll W105M an indispensable asset for metal drilling tasks.

Detailed Breakdown of Key Features

The Xendoll W105M is built around a core philosophy of delivering professional-grade performance in a user-friendly package. Let's explore the features that contribute to its superior functionality.

1. High-Power Design for Unstoppable Performance

At the heart of the Xendoll W105M is a robust and powerful motor. This isn't just about raw speed; it's about consistent, stable power under load. When drilling through tough metals, a weak motor can stall, overheat, or produce uneven holes. The W105M’s high-power design ensures that it maintains steady rotational force, allowing it to cut through materials quickly and cleanly. This means you can complete your drilling tasks faster, reduce wear on drill bits, and handle a wider range of material thicknesses without hesitation. For mechanical dealers and high-volume users, this translates directly into increased throughput and reduced project time.

2. Precision Positioning for Flawless Accuracy

Power is useless without control. The Xendoll W105M addresses this with its advanced positioning system. This feature is critical for tasks requiring pinpoint accuracy, such as creating mounting holes for machinery or intricate parts for a custom project. The system ensures that every drill bit placement is exact, virtually eliminating misaligned holes. This precision saves material, time, and frustration. For educational equipment dealers, this is a vital teaching point, allowing students to learn the importance of accuracy in machining. For machining enthusiasts, it means professional-level results on DIY projects.

3. Durable Construction for Long-Term Reliability

A tool is an investment, and the W105M is built to last. Its heavy-duty body is constructed from high-quality materials designed to withstand the rigors of a busy workshop. The solid construction minimizes vibrations during operation, which is crucial for both accuracy and the longevity of the machine itself. This durability ensures lasting stability, meaning the machine will perform as reliably on its thousandth job as it did on its first. For overseas mechanical distributors, offering a product known for its durability builds trust and reduces warranty claims, while for end-users, it means a tool they can depend on for years to come.

4. User-Friendly Interface for All Skill Levels

Sophisticated technology should be accessible, and the Xendoll W105M excels with its intuitive and easy-to-adjust functions. The controls are logically laid out, and adjustments for speed and depth are straightforward. This makes the machine suitable for everyone from seasoned professionals to those just beginning their machining journey. Hobbyists will appreciate the short learning curve, while professionals will value the efficiency gained from quick and easy setup changes. This versatility makes the W105M a perfect fit for diverse markets, from well-equipped industrial workshops to school labs and home garages.

5. Integrated Safety Features for Peace of Mind

No workshop tool is complete without comprehensive safety measures. The Xendoll W105M is equipped with multiple safety protections to safeguard the user. These features are designed to prevent common workshop accidents, creating a secure operating environment. This is especially important for educational institutions where student safety is the top priority, and for any user who values a worry-free working experience. Knowing that the machine has built-in safety mechanisms allows the operator to focus entirely on the task at hand.

Conclusion

In summary, the Xendoll W105M Metal Drilling Machine is more than just a tool; it's a comprehensive solution for anyone serious about metalworking. By seamlessly integrating high-power performance, meticulous precision, rugged durability, user-centric design, and essential safety features, it stands as a top-tier choice for its intended audiences. For overseas mechanical dealers, it's a reliable and profitable product line. For educational equipment distributors, it's a safe and effective teaching tool. And for machining enthusiasts, it's the key to unlocking new levels of craftsmanship in their projects.

Choosing the Xendoll W105M means investing in a tool that guarantees perfect results and ensures your projects proceed smoothly from start to finish. Ready to upgrade your workshop capabilities? Explore the full specifications and discover the difference precision engineering makes at xendolltools.com.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options