Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Aug 08, 2025

Aug 08, 2025

1043

1043

At first glance, a metal lathe and a wood lathe might seem similar – both rotate material against a cutting tool. This leads many DIY enthusiasts and even some professionals to wonder: "Why can't I just use my metal lathe for woodturning?" While technically possible for very limited, crude work, using a metal lathe for woodturning is strongly discouraged and often unsafe. Understanding the fundamental differences in design, operation, and purpose reveals why each machine excels in its domain but fails in the other.

The Core Differences: Purpose Dictates Design

Speed Requirements: High Torque vs. High RPM

Metal Lathes: Designed for machining dense, hard metals. They prioritize high torque at low to medium RPMs (often ranging from 50 to 2,000 RPM, sometimes higher on smaller models). This provides the necessary power for removing metal chips gradually and precisely without damaging the tool or workpiece.

Wood Lathes: Wood is softer but fibrous. Effective cutting requires very high surface speeds achieved through much higher RPMs (typically 500 to 4,000 RPM, sometimes even higher for small spindles). High RPM creates a cleaner shearing cut through the wood fibers. Metal lathes simply cannot spin fast enough for efficient or clean woodturning.

Tool Design & Presentation: Rigid Support vs. Handheld Finesse

Metal Lathes: Utilize rigidly mounted single-point cutting tools held in a compound rest or turret. The tool is precisely positioned and fed mechanically against the workpiece. Control is paramount for dimensional accuracy and surface finish on metal.

Wood Lathes: Primarily use handheld gouges, chisels, and scrapers guided by the turner on a tool rest. The "bevel-rubbing" technique provides control and leverage unique to woodturning. Attempting to use handheld woodturning tools safely on a metal lathe is nearly impossible due to the lack of a proper, adjustable tool rest designed for ergonomics and safety. Rigid metal tools lack the necessary geometry and presentation for efficient wood removal.

Machine Structure & Chip Management: Enclosed Precision vs. Open Debris

Metal Lathes: Built for extreme rigidity and precision (often measured in thousandths of an inch/microns). They feature enclosed or guarded beds to contain hard, sharp metal chips and cutting fluids. The ways (slides) are precision-ground and protected from debris.

Wood Lathes: Have a more open design to facilitate easy access for handheld tools and clear visibility. They are built to manage large volumes of stringy or dusty wood shavings, which fall away freely. Wood dust and shavings quickly infiltrate the precision ways, gears, and bearings of a metal lathe, causing rapid wear, clogging lubrication systems, and potentially jamming critical components. Cleaning is difficult and ineffective.

Safety Hazards: The Critical Dangers

Dust Explosion & Fire: Wood dust is highly combustible. Containing it within the enclosed structure of a metal lathe creates a significant fire and explosion hazard, especially near electrical components or sparks.

Catastrophic Failure: Wood, especially unbalanced blanks or pieces with hidden flaws, can generate tremendous centrifugal force at high RPMs. Metal lathe chucks and spindles are designed for metal's density and predictable clamping. Using them for wood risks the wood shattering or flying loose at dangerous speeds if the grip fails or the wood fractures.

Tool Catching & Kickback: Handheld woodturning tools used without a proper woodturning tool rest are incredibly prone to catching in the wood grain. On a metal lathe, this can violently wrench the tool from the operator's hands, leading to severe injury or damage to the machine (kickback).

Dust Inhalation: Without the open design and often integrated dust collection ports of a wood lathe, operators are exposed to high concentrations of harmful wood dust within the metal lathe's enclosure.

Lack of Essential Woodturning Features

Tool Rest: Metal lathes lack the robust, easily adjustable, and ergonomically positioned tool rest fundamental to safe and controlled woodturning.

Tailstock Design: Woodturning tailstocks often feature live centers (rotating) specifically designed to handle the thrust of turning wood without burning it. Metal lathe tailstocks might use dead centers (stationary) unsuitable for wood.

Speed Control: Rapid, easy speed changes are crucial in woodturning as piece diameter changes. Metal lathes typically have slower, more complex speed adjustment processes.

Conclusion: Choose the Right Tool for the Job

While the rotating principle is shared, metal lathes and wood lathes are engineered for fundamentally different materials and processes. Using a metal lathe for woodturning compromises safety, machine integrity, efficiency, and results. The incompatible speeds, tool presentation methods, dust hazards, and lack of essential safety features make it a risky and impractical choice.

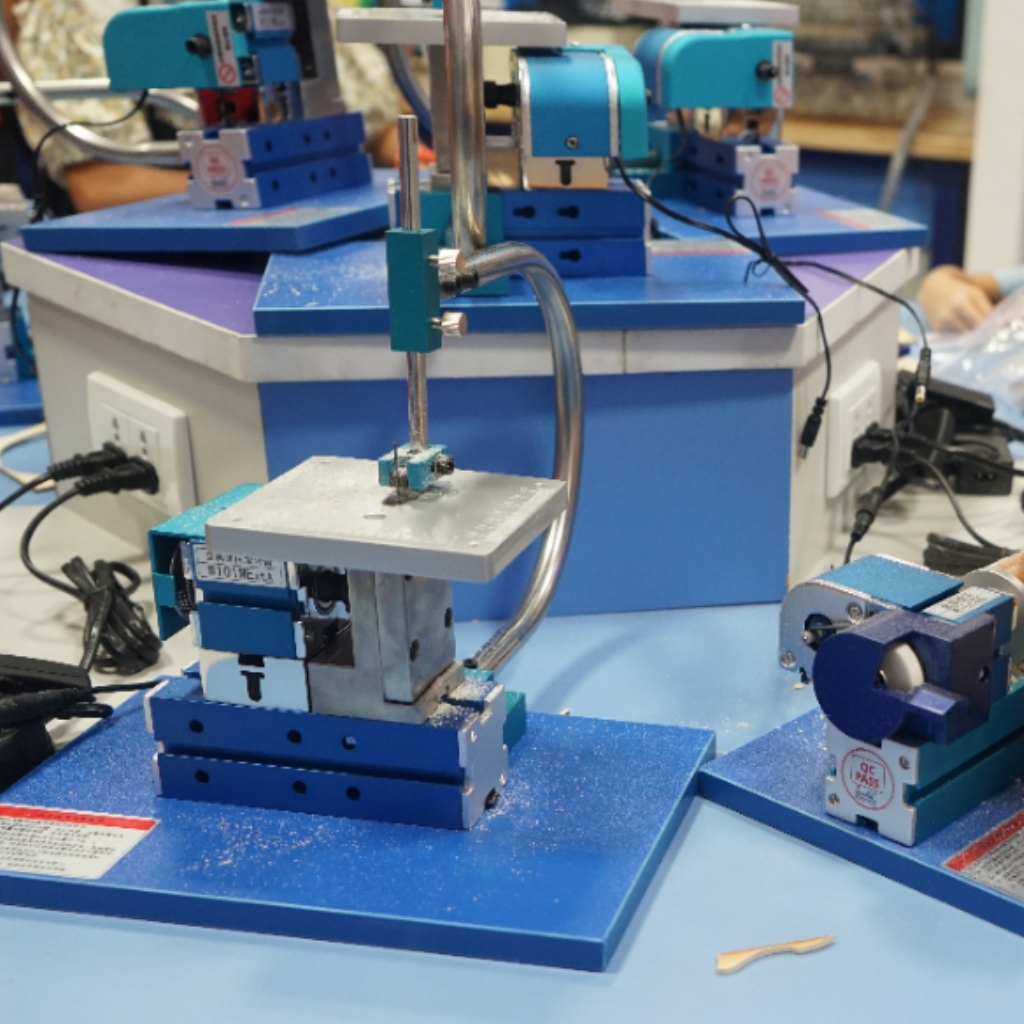

For exceptional woodturning results and, most importantly, operator safety, invest in a purpose-built wood lathe. Explore Xendoll's range of precision mini wood lathes, designed specifically for the unique demands of woodturning – offering the high RPM, open structure, robust tool rests, and safety features needed to unleash your creativity safely and effectively. Discover the perfect tool for your craft at xendolltools.com.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options