Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Aug 04, 2025

Aug 04, 2025

1022

1022

The headstock of a lathe isn't just another component; it's the command center for rotation, power transmission, and ultimately, precision. Its material composition directly impacts your machine's vibration damping, rigidity, stability, and longevity. Understanding the "what" and "why" behind headstock materials is crucial for anyone selecting, using, or selling lathes, from industrial workshops to educational labs and hobbyist garages. Let's delve into the common materials used and the critical factors driving their selection.

I. The Reigning Champion: Cast Iron (Gray Iron & Ductile Iron)

Overwhelmingly, cast iron, particularly gray iron (flake graphite iron) and increasingly ductile iron (nodular graphite iron), is the material of choice for the vast majority of lathe headstocks, especially for mini-lathes, bench-top models, and industrial workhorses. Here's why it dominates:

Exceptional Vibration Damping: This is cast iron's superpower. The graphite flakes (in gray iron) or nodules (in ductile iron) within its structure act as millions of microscopic dampers, effectively absorbing and dissipating vibrational energy generated by the motor, gears, and cutting process. This results in significantly smoother surface finishes and allows for finer, more precise cuts – a non-negotiable for quality machining.

Inherent Rigidity and Stability: Cast iron provides excellent stiffness and dimensional stability under load and varying temperatures. It resists deflection, ensuring the spindle axis remains true during cutting operations, critical for maintaining accuracy over time.

Good Machinability & Cost-Effectiveness: While hard, cast iron is readily cast into the complex shapes required for headstock housings (incorporating bearing bores, gear chambers, mounting points) and then machined to precise tolerances. This makes it a highly economical choice for mass production without sacrificing core performance.

Wear Resistance: The graphite structure also provides inherent lubricity, contributing to good wear characteristics on internal sliding surfaces like gear shafts.

II. Alternative Contenders: Steel Fabrications & Alloys

While less common for the main headstock housing, other materials play roles, particularly in specific designs or components:

Steel Fabrications (Welded/Modular):

Pros: Offers potentially higher tensile strength and rigidity-to-weight ratio than cast iron. Can be advantageous for very large, custom lathes or designs prioritizing lighter weight (though weight is often desired for stability in lathes).

Cons: Significantly poorer vibration damping compared to cast iron. Welded structures can be prone to residual stresses and distortion. Achieving the same level of damping often requires complex (and expensive) internal damping treatments or polymer composites. Generally less cost-effective for complex shapes than casting.

Usage: Primarily found in some large, custom industrial lathes or specialized applications where weight constraints override vibration concerns. More common for ancillary frames than the core headstock housing itself.

Precision Alloys (For Specific Components):

Bearing Housings/Saddles: High-strength alloy steels (like 4140 or 4340) are often used for the sleeves or cartridges that directly hold the spindle bearings. These are precision-ground, heat-treated (hardened and tempered), and sometimes honed to provide the ultimate rigid, wear-resistant, and dimensionally stable support for the critical spindle bearings.

Gears/Shafts: Headstock gears and shafts are typically forged or machined from high-quality alloy steels (e.g., carburizing grades like 8620 or through-hardening grades like 4140) and undergo heat treatment (case hardening, nitriding, through hardening) for extreme surface hardness, wear resistance, and core toughness to handle transmission loads.

III. Material Selection: Balancing the Critical Factors

Choosing the headstock material involves a careful trade-off:

Vibration Damping: Paramount for surface finish and precision. Cast iron wins decisively.

Rigidity & Stability: Essential for accuracy under load. Cast iron and steel both excel, but cast iron's stability is often superior.

Damping/Rigidity Ratio: This is where cast iron truly shines – offering excellent damping and sufficient rigidity at a practical cost.

Complexity of Shape: Casting is ideal for the intricate internal passages and chambers of a headstock.

Cost & Manufacturability: Cast iron offers the best balance for volume production of complex parts.

Weight: Generally, more mass is beneficial in a lathe headstock for stability. Cast iron provides this naturally.

Conclusion: Cast Iron - The Engineered Foundation for Precision Turning

For the vast majority of lathes – from the compact mini-lathes beloved by enthusiasts and educators to the robust industrial machines powering production lines – cast iron (gray iron or ductile iron) remains the unequivocal champion for the headstock housing. Its unparalleled ability to dampen harmful vibrations while providing essential rigidity and stability makes it the fundamental material choice for achieving the precision and surface quality that machinists demand. While high-strength steels play vital roles in critical internal components like bearing supports and gears, the core structure relies on the unique properties of cast iron.

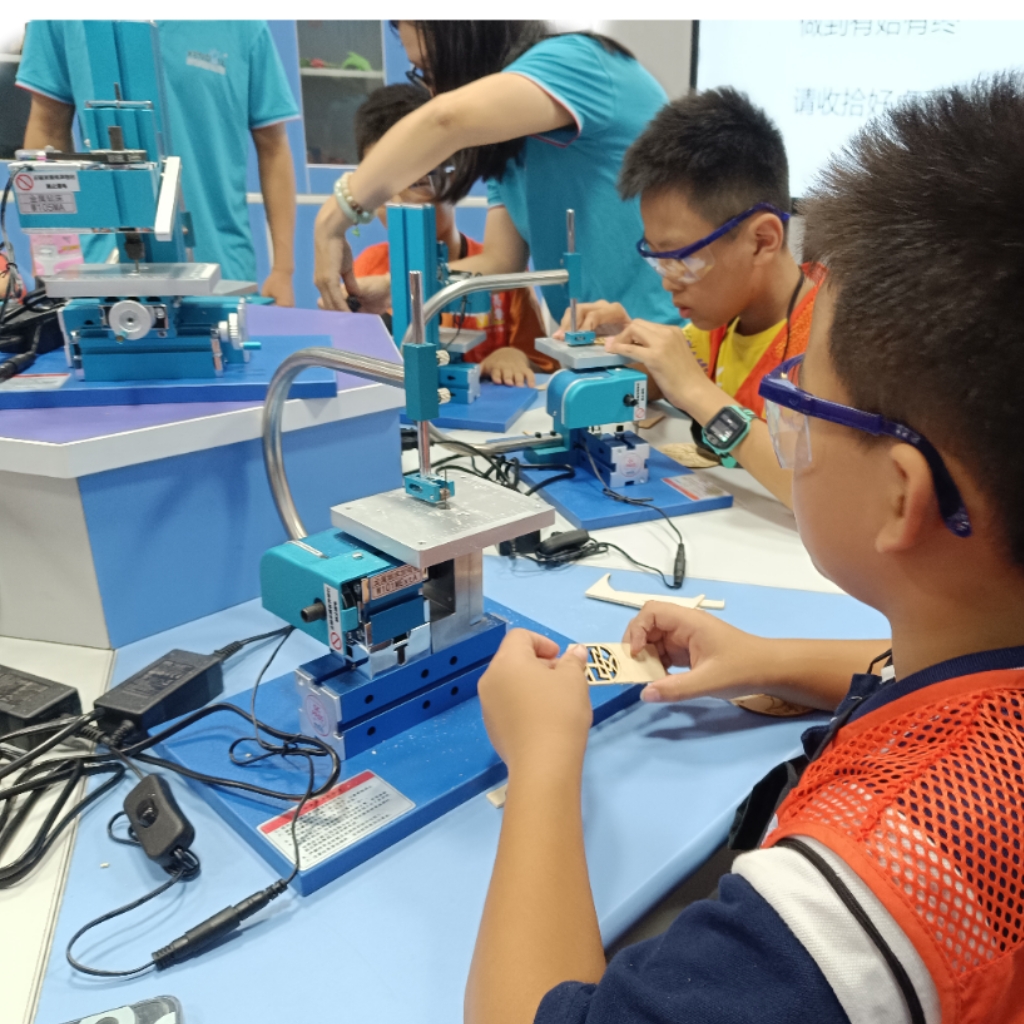

At Xendoll Tools, we understand that the foundation of a great lathe starts with its core components. Our mini-lathes and precision tools utilize carefully selected cast iron for critical structures like the headstock, ensuring optimal vibration damping and stability right from the start. This commitment to fundamental engineering principles ensures our machines deliver the reliable performance and quality results expected by overseas machinery distributors, educational institutions, and dedicated machining hobbyists. When evaluating a lathe, look beyond the surface – the material in its heart, the headstock, speaks volumes about its potential for precision and durability. Discover the Xendoll difference at xendolltools.com.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options