Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Sep 17, 2025

Sep 17, 2025

835

835

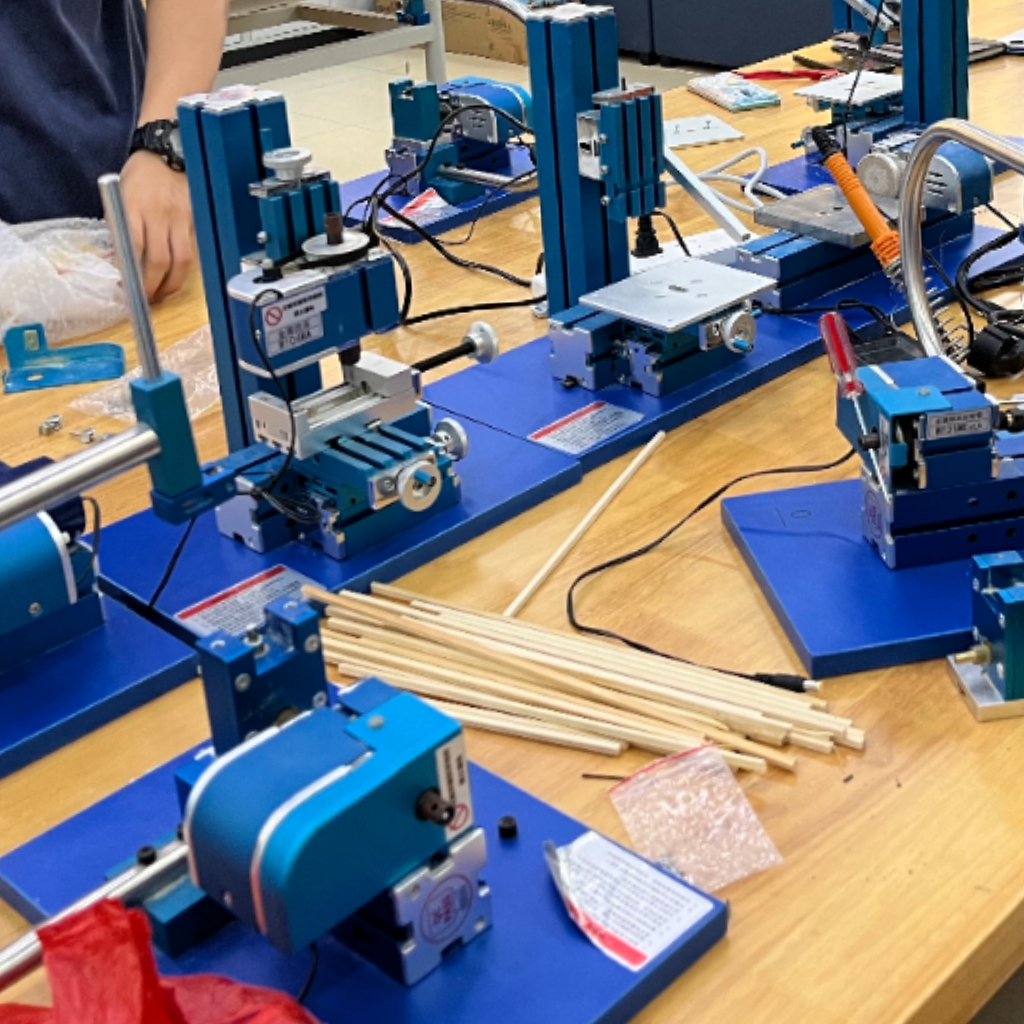

In the dynamic world of STEM education, theoretical knowledge is only half the battle. True understanding blossoms when students can translate abstract concepts from their math and science textbooks into tangible, physical creations. This is where the right equipment becomes not just helpful, but essential. Mini machines and desktop CNC tools bridge the gap between digital design and physical reality, fostering a hands-on learning environment that inspires creativity, problem-solving, and genuine engineering intuition. For educators and school equipment dealers seeking to build a premier STEM lab, selecting the right machinery is paramount. Here are our favorite types of machines that are revolutionizing STEM classrooms worldwide.

1. The Versatile Desktop CNC Mill: The Digital Manufacturing Powerhouse

A desktop CNC (Computer Numerical Control) mill is arguably the cornerstone of a modern STEM lab. It’s a versatile workhorse that teaches the entire digital fabrication workflow.

Applied Learning: Students learn to create 2D and 3D designs using CAD (Computer-Aided Design) software, then generate toolpaths with CAM (Computer-Aided Manufacturing) software, and finally, watch as the machine precisely executes their code by cutting materials like wax, modeling board, soft metals, and plastics.

Key STEM Concepts: This process encapsulates a vast array of STEM principles: precision engineering, computer programming (G-code), geometric mathematics, material science, and mechanical design.

Why It's a Favorite: The CNC mill provides a direct link between the virtual and physical worlds. The thrill of seeing a digital model become a physical part is unmatched and teaches invaluable lessons in precision and iteration—if a design has a flaw, the physical part will show it, encouraging debugging and improvement.

2. The Compact Lathe: Teaching the Principles of Rotation and Symmetry

The lathe is a classic tool machine that introduces students to the fundamental principles of machining rotational parts. Modern mini lathes are perfectly sized, safe, and affordable for classroom use.

Applied Learning: Students can learn to create everything from simple cylindrical pins and chess pieces to more complex threaded parts and pulleys. It teaches the importance of measurement, tolerance, and symmetry.

Key STEM Concepts: Operating a lathe reinforces understanding of rotational kinematics, axes of rotation, material removal processes, and metrology (the science of measurement). It provides a hands-on lesson in physics and geometry.

Why It's a Favorite: The lathe offers a foundational machining experience that has been essential for centuries. It builds manual dexterity, spatial reasoning, and a deep respect for traditional craftsmanship complemented by modern precision.

3. The DIY 3-in-1 Machine Mill/Lathe/Drill Press: The Ultimate Space-Saver for Collaborative Learning

For schools with limited space or budget, a 3-in-1 combination machine (mill, lathe, and drill press) is an exceptional choice. It offers incredible functionality in a single, compact footprint.

Applied Learning: This type of machine allows a single workstation to support a wide variety of projects. A student can turn a part on the lathe, drill precisely located holes using the drill press attachment, and then mill a flat surface or a slot—all without changing machines.

Key STEM Concepts: It emphasizes modular design, mechanical adaptation, and resource optimization. Students learn how different machining processes can be integrated to complete a complex project from a single piece of material.

Why It's a Favorite: Its versatility is its greatest strength. It enables project-based learning where students must plan and execute multi-step manufacturing processes, mimicking how real-world products are made. It’s perfect for encouraging teamwork and project management in a group setting.

4. The Accessory Ecosystem: Vises, Tool Kits, and Safety Gear

The machines themselves are only part of the equation. A proper STEM lab is equipped with high-quality accessories that ensure safety, precision, and ease of use.

Applied Learning: Machine Vises: Teach the importance of secure workholding for achieving accuracy and preventing accidents.

Tooling Kits: Different cutters, drills, and inserts allow students to experiment with the right tool for the job, understanding how tool geometry affects the cut.

Safety Equipment: Safety glasses and proper training instill a culture of safety and responsibility that is critical in any engineering environment.

Why It's a Favorite: These components teach essential workshop etiquette and operational best practices. Learning to set up a machine correctly with the right tools is as important as operating it.

Conclusion: Building a Foundation for Future Engineers

Investing in the right miniature machine tools is an investment in the future of your students. These machines do more than just shape metal and plastic; they shape minds. They build confidence, demystify technology, and provide the practical skills that are highly sought after in today’s high-tech industries.

At Xendoll Tools, we are passionate about supporting STEM education. We design our mini lathes, desktop CNC mills, and versatile 3-in-1 machines with the educator and student in mind: prioritizing safety, reliability, and educational value. Our machines are the perfect fit for schools, vocational training programs, and university engineering departments looking to provide a hands-on, impactful learning experience.

Ready to equip your STEM classroom for success? Explore our full range of educational machinery and accessories designed to inspire the next generation of creators and innovators at xendolltools.com.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options