Blog

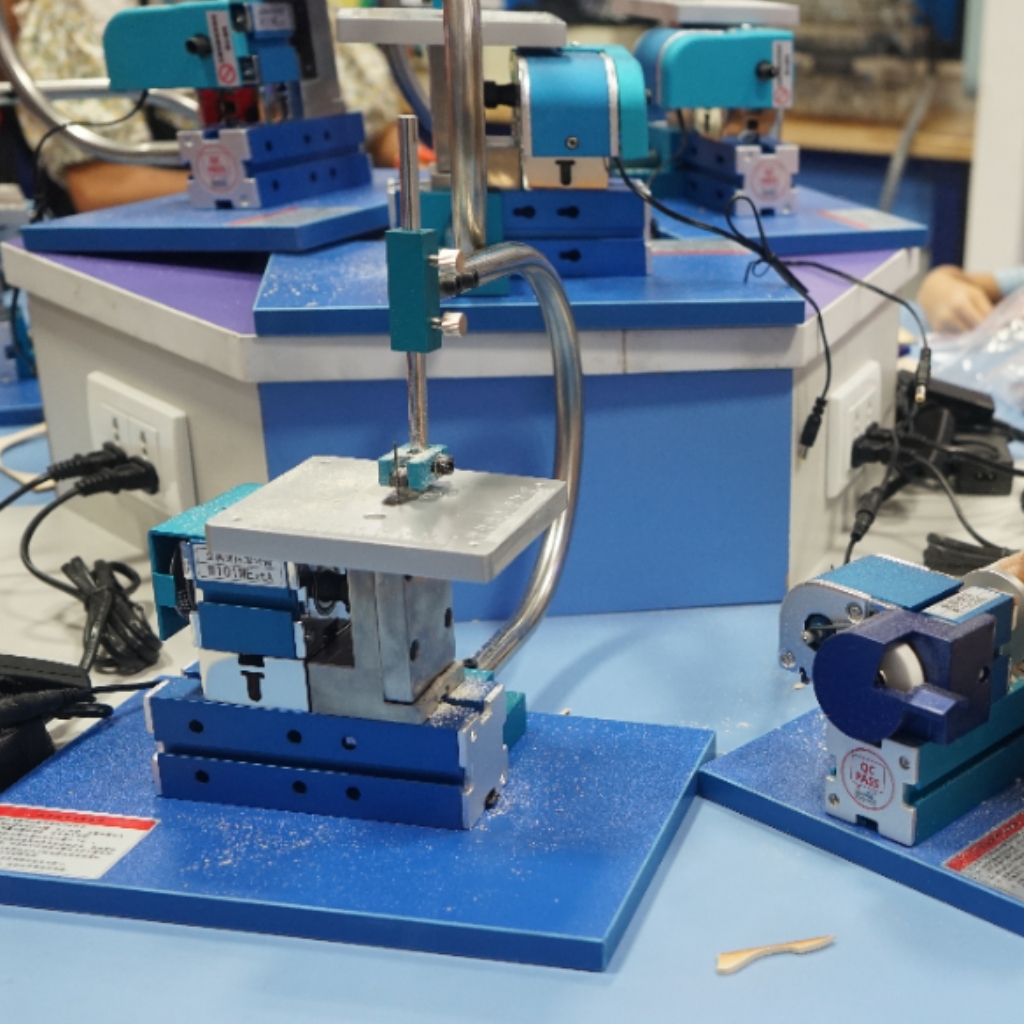

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Aug 09, 2025

Aug 09, 2025

1015

1015

Woodturning on a lathe unlocks incredible creative potential, transforming raw timber into beautiful, functional objects. However, every tool has its boundaries, and understanding the inherent limitations of a wood lathe – especially benchtop or mini models – is crucial for success, safety, and managing expectations. Knowing these constraints helps you select the right projects, operate the machine effectively, and achieve the best possible results.

1. Size and Capacity Constraints: The Physical Boundaries

* Swing Over Bed: This is the maximum diameter of workpiece the lathe can handle. A common limitation for mini lathes (like many Xendoll models) is a swing of 10-14 inches. Attempting a bowl larger than this simply isn't physically possible without modifications or a larger machine.

* Distance Between Centers (DBC): This dictates the maximum length of a spindle (like a table leg or rolling pin) you can turn. Exceeding this length means the workpiece won't fit or won't be properly supported, leading to dangerous vibration and poor results.

* Weight Limits: Lathes, especially compact ones, have maximum recommended workpiece weights. Heavy, dense blanks can strain the motor, bearings, and overall structure, causing premature wear or failure.

2. Power and Torque: Taming Tough Timber

* Motor Horsepower (HP): Mini and benchtop lathes often feature motors in the 0.5 HP to 1 HP range. This is sufficient for most spindle work and smaller bowls in softer woods. However, the primary limitation arises when tackling large diameter blanks or very hard, dense exotic woods. The motor can bog down, stall, or struggle to maintain consistent speed under heavy cuts.

* Cutting Aggression: Lower power necessitates lighter, more patient cuts. Aggressive deep cuts on demanding material will quickly overwhelm a smaller motor, leading to rough surfaces, tool chatter, and potential catches.

3. Speed Range and Control: Finding the Sweet Spot

* Maximum Speed: While high speeds are great for finishing, some mini lathes may have a lower top speed (e.g., 3000-4000 RPM) compared to larger industrial machines. This can sometimes limit the absolute finest finishes achievable on very small spindles, though it's often perfectly adequate.

* Minimum Speed & Step Gaps: A more common limitation is a minimum speed that's still too high for safely roughing out large, unbalanced blanks. Additionally, lathes with fewer speed steps (or relying solely on electronic variable speed) might have gaps where the ideal speed for a specific diameter/wood combination isn't perfectly available.

4. Rigidity and Vibration: The Stability Factor

* Benchtop Design: Smaller lathes, by their nature, have less mass and sometimes less robust construction than floor-standing models. This can make them more susceptible to vibration, especially when turning unbalanced blanks or pushing the size/weight limits.

* Consequences of Vibration: Vibration is the enemy of precision and smooth finishes. It causes tool chatter (leaving unwanted patterns), makes delicate cuts difficult, increases wear on the lathe and tools, and can be uncomfortable for the turner. Careful blank preparation and balancing become even more critical.

5. Precision and Repeatability (For Production)

* Manual Operation: Wood lathes are primarily freehand tools. While jigs exist (duplicators, etc.), achieving micrometer-level precision or perfectly identical parts consistently is inherently challenging and time-consuming compared to CNC machining. They excel at unique artistic pieces rather than mass-produced identical components.

6. Accessory Compatibility and Cost

* Specialized Tools: Expanding capabilities often requires accessories like large chucks, specialized steady rests, or outboard turning attachments. A significant limitation can be the cost of these accessories and ensuring they are compatible with your specific lathe model's spindle thread or bed design.

* Tool Rest Limits: The standard tool rest length may be insufficient for very long spindles, requiring additional rests or extensions.

Conclusion: Limitations Define Possibility, Not Failure

Understanding the limitations of your wood lathe isn't about highlighting weaknesses; it's about working intelligently within its design parameters. A mini or benchtop lathe's "limitations" in size and power are directly related to its strengths: affordability, space efficiency, and accessibility for hobbyists, educational settings, and specialized workshops. By respecting these boundaries – choosing appropriate project sizes, using sharp tools, taking lighter cuts on hard materials, minimizing vibration, and understanding the machine's power curve – you unlock its true potential. Knowing that a benchtop lathe isn't suited for massive 24-inch bowls allows you to focus on the incredible range of projects it is perfect for: intricate pens, beautiful small bowls, elegant spindles, and a world of creative expression. Choose the right tool for your vision, respect its limits, and enjoy the satisfyingcraft of woodturning.

For details, please refer to the following link:

https://www.xendolltools.com/category/micro-cnc-machine.html

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options