Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jun 04, 2025

Jun 04, 2025

1102

1102

In today's rapidly evolving technological landscape, equipping students with practical skills is no longer optional—it's imperative. While theoretical knowledge forms the foundation, true understanding and innovation blossom through hands-on application. Enter the mini lathe, a transformative tool rapidly becoming the cornerstone of effective Science, Technology, Engineering, and Mathematics (STEM) programs worldwide. Far more than just a scaled-down machine, a robust mini lathe, like those engineered by XendollTools, offers an unparalleled platform for bridging abstract concepts with tangible reality, fostering critical thinking, and igniting passion for manufacturing and engineering. Let's explore how this compact powerhouse is reshaping STEM education.

1. Bridging Theory and Practice: Making Abstract Concepts Tangible

* Physics in Action: Concepts like rotational dynamics, force, friction, material properties, and energy transfer cease to be equations on a whiteboard. Students see and feel the effects of cutting speed, feed rate, and tool geometry on different materials (aluminum, brass, plastics). They directly experience torque, understand inertia, and learn why rigidity matters.

* Geometry & Trigonometry Applied: The lathe transforms abstract angles, diameters, radii, and tolerances into critical parameters for success. Calculating depths of cut, understanding tapers, setting compound slide angles, and achieving precise dimensions bring math to life in a visceral, unforgettable way.

* Materials Science Unveiled: Students directly compare how aluminum, brass, steel, and engineering plastics behave under the cutting tool. They learn about hardness, ductility, machinability, and the effects of heat generation, providing a concrete foundation in materials engineering principles.

* Engineering Design Cycle Embodied: Mini lathes enable the full cycle: design (CAD optional), material selection, process planning (sequence of operations), fabrication (machining), testing, and iterative refinement. Students learn why design-for-manufacturability (DFM) matters as they encounter real-world fabrication challenges.

2. Cultivating Foundational Technical Skills & Safety Mindset

* Core Machining Competencies: Operating a mini lathe teaches fundamental skills vital across engineering disciplines: measurement (calipers, micrometers), workholding (chucks, collets, centers), tool selection & geometry, speed/feed calculation, blueprint reading, and precision workmanship. These are directly transferable to advanced manufacturing and prototyping.

* Mastering Measurement & Metrology: The demand for precision inherent in lathe work forces students to become proficient and meticulous with measurement tools, understanding tolerances and the critical importance of accuracy. This skill alone is invaluable across countless technical fields.

* Ingraining Safety Culture: A well-managed mini lathe program provides the perfect environment to instill a rigorous safety mindset. Students learn the importance of PPE (safety glasses, no loose clothing), machine guarding awareness, safe setup procedures, emergency stops, and hazard recognition in a controlled setting – lessons that last a lifetime.

* Problem-Solving Under Pressure: Things don't always go as planned. A tool chatters, a dimension is off, a setup fails. Lathe work demands analytical troubleshooting, forcing students to diagnose issues, research solutions, and adapt their approach – developing critical resilience and technical intuition.

3. Fostering Creativity, Innovation, and "Maker" Confidence

* From Consumer to Creator: Mini lathes empower students to move beyond assembling kits to designing and fabricating their own custom components. This shift – from passive consumer to active creator – is profoundly empowering and sparks genuine innovation.

* Project-Based Learning Catalyst: The lathe becomes the engine for diverse, engaging projects: building mini-engines, robotics components, custom scientific instrument parts, architectural models, functional art pieces, or solutions to community challenges. The possibilities are limited only by imagination.

* Building Confidence Through Competence: Successfully machining a part to precise specifications delivers an unmatched sense of accomplishment. This tangible proof of skill builds immense confidence in students' technical abilities and encourages them to tackle increasingly complex challenges.

* Interdisciplinary Integration: Lathe projects naturally integrate multiple STEM disciplines. A robotics project involves mechanical design (lathe parts), electronics, programming, and physics. A wind turbine model combines aerodynamics, energy conversion, and precision fabrication.

4. Preparing for Future Careers & Technological Fluency

* Direct Pathway to Advanced Manufacturing: Mini lathes provide the foundational skills upon which CNC machining, advanced CAM programming, and modern manufacturing techniques are built. Students gain a crucial head start in understanding subtractive manufacturing processes.

* Understanding the "How" Behind the "What": In a world of mass-produced goods, understanding how things are actually made is a rare and valuable skill. Lathe work demystifies manufacturing, providing insight into processes, materials, and the value of precision engineering.

* Developing CAD/CAM Fluency: Many modern mini lathes, including CNC-ready options from XendollTools, seamlessly integrate with CAD/CAM software. Students learn the critical link between digital design and physical production, a core competency in Industry 4.0 careers.

* Spark for Engineering & Trades: Hands-on experience with precision machinery is a powerful motivator. Mini lathes can ignite passion for careers in mechanical engineering, machining, tool & die making, aerospace, automotive, robotics, and skilled technical trades – fields facing significant talent shortages.

5. Why XendollTools Mini Lathes Excel in the STEM Environment

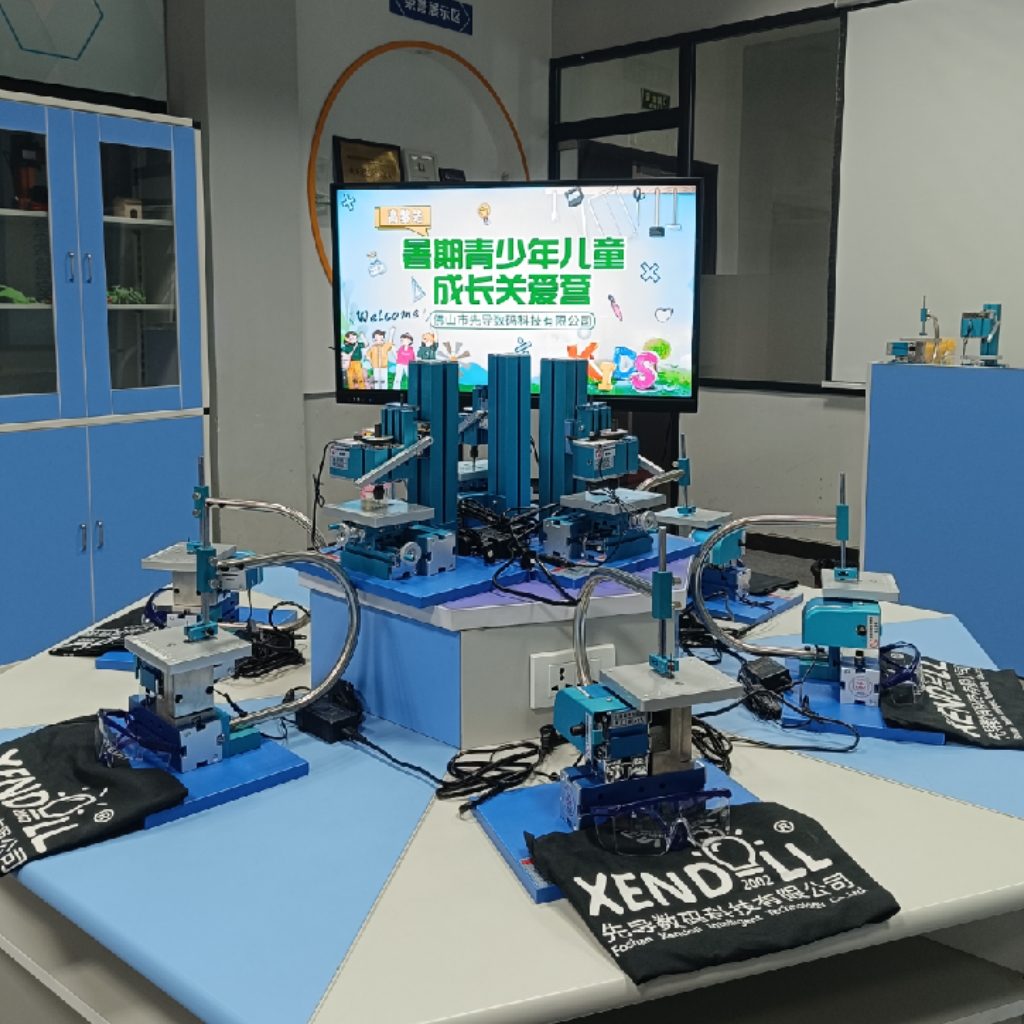

* Designed for Education: XendollTools offers models specifically chosen or configured for educational settings, balancing capability, safety features, and ease of use. Robust construction ensures durability in demanding classroom or lab environments.

* Classroom-Safe & Manageable: Benchtop size allows safe installation in standard labs and workshops without requiring industrial infrastructure. Features like emergency stops, splash guards, and stable bases enhance safety protocols.

* Precision That Inspires: Consistent, reliable precision ensures student projects succeed when procedures are followed correctly, reinforcing learning and building confidence. High-quality components minimize frustrating downtime.

* Scalability & Growth: From introductory manual models to advanced CNC-ready or full CNC lathes, XendollTools provides a pathway for programs to grow alongside student skill levels, offering long-term value for institutions.

* Supporting Educators: XendollTools understands the needs of educators, offering resources and machines that integrate effectively into structured curricula and project-based learning frameworks.

Conclusion: The Mini Lathe – An Indispensable Engine for Future-Ready STEM Learning

The mini lathe is far more than just a machine tool in the STEM classroom; it is a catalyst for profound learning, skill development, and inspiration. Its unique ability to make abstract STEM principles tangible, cultivate essential technical and safety skills, unleash creativity through project-based learning, and provide a direct link to high-demand careers makes it an invaluable investment in the future.

By placing the power of precision metalworking into the hands of students within the safe, accessible format of a benchtop machine, educators unlock a world of possibilities. Students transition from passive learners to active engineers and makers, developing not only technical competence but also critical problem-solving abilities, resilience, and a deep-seated confidence in their capacity to shape the physical world.

For schools, universities, makerspaces, and technical programs committed to delivering truly impactful, future-oriented STEM education, integrating high-quality mini lathes like those from XendollTools is not just an enhancement—it's becoming a necessity. It equips students with the foundational skills, practical mindset, and innovative spirit needed to thrive in the technologically advanced world they will inherit and lead.

Empower the next generation of innovators and engineers. Explore XendollTools' range of precision mini lathes designed for durability, safety, and educational excellence. Discover how the right tool can transform your STEM curriculum at https://xendolltools.com.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options