Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

May 26, 2025

May 26, 2025

1125

1125

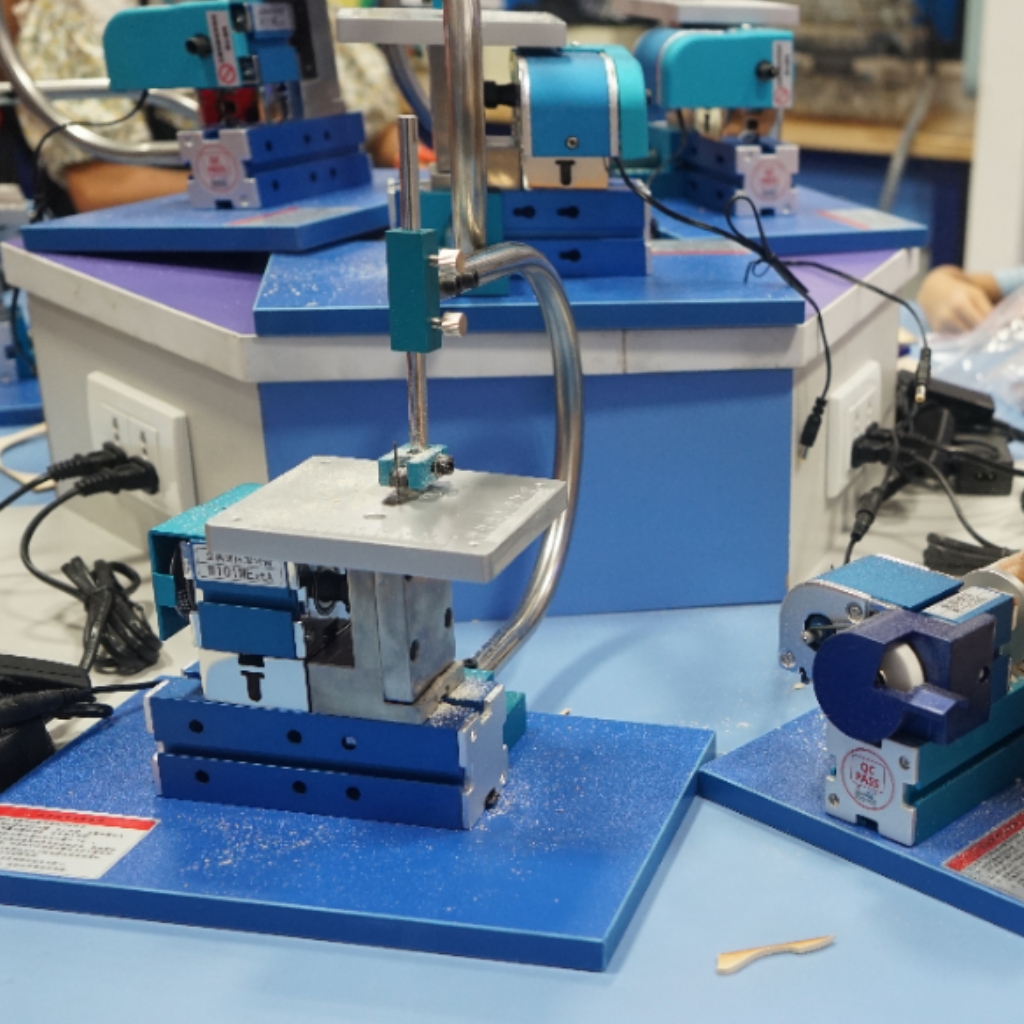

The lathe machine, one of humanity’s oldest and most versatile tools, has shaped industries for centuries. From crafting intricate wooden components to machining precision metal parts, lathes remain indispensable in manufacturing. But beyond industrial applications, these machines are now playing a transformative role in STEM education. Compact, user-friendly mini lathes, especially those integrated with CNC lathes technology, are empowering students and educators to bridge theoretical knowledge with hands-on skills. In this article, we explore the purpose of lathe machines, their evolution, and how mini lathes like those from Xendoll Tools (xendolltools.com) are revolutionizing STEM learning for future engineers, designers, and innovators.

A lathe machine is designed to rotate a workpiece on its axis while a cutting tool shapes it symmetrically. This fundamental process, known as "turning," allows the creation of cylindrical, conical, or curved components with high precision. Here’s a breakdown of its primary functions:

Material Removal: Lathes carve away excess material (wood, metal, or plastic) to achieve desired shapes.

Precision Machining: They ensure dimensional accuracy, critical for parts like screws, shafts, and gears.

Versatility: Lathes perform drilling, grooving, threading, and knurling operations.

Reproducibility: Once programmed, lathes can replicate components consistently—essential for mass production.

Historically, lathes were manually operated, but modern advancements like CNC lathes (Computer Numerical Control) have automated processes, enhancing speed and precision.

Lathe machines are the backbone of industries ranging from aerospace to automotive. CNC lathes, in particular, dominate high-volume production due to their efficiency and ability to handle complex designs. However, their role extends beyond factories:

Custom Fabrication: Small workshops use lathes for bespoke projects, from jewelry to robotics.

Repair & Maintenance: Lathes restore worn-out parts, reducing waste and costs.

Innovation Hubs: Makerspaces and tech labs leverage lathes for prototyping inventions.

But one of the most exciting developments is their adoption in STEM education—a trend accelerated by the rise of mini lathes.

STEM (Science, Technology, Engineering, and Mathematics) programs thrive on experiential learning. Mini lathes, such as those offered by Xendoll Tools, provide a safe, scalable way to introduce machining concepts to students. Here’s how they align with educational goals:

Physics in Action: Students observe torque, rotational motion, and material properties firsthand.

CNC Integration: Mini CNC lathes teach programming, CAD/CAM software, and automation—skills critical for Industry 4.0 careers.

Problem Solving: Troubleshooting setups or tool alignment fosters critical thinking.

Compact designs minimize risks associated with industrial machinery.

Speed controls and emergency stops ensure student safety.

Lightweight frames allow easy placement in classrooms or home workshops.

Schools and hobbyists can afford mini lathes without sacrificing functionality.

Reduces material waste compared to full-scale industrial machines.

Students design and fabricate real-world projects, from robotic parts to art installations.

Collaborative projects simulate real engineering workflows.

At Xendoll Tools (xendolltools.com), we design mini lathes tailored for educators, hobbyists, and small-scale manufacturers. Our machines combine industrial-grade precision with user-friendly features:

Adaptable CNC Compatibility: Upgrade manual lathes with CNC kits for advanced projects.

Durable Construction: Steel frames and high-torque motors handle diverse materials.

Educational Packages: Bundled software, tutorials, and project blueprints streamline curriculum integration.

For example, a high school in Texas used Xendoll’s mini CNC lathes to teach students how to program and produce aluminum robot joints—an exercise that blended coding, physics, and teamwork.

Project: Designing a Wind Turbine Model

Objective: Teach renewable energy concepts and mechanical engineering basics.

Tools Used: Xendoll mini lathe, CAD software, and lightweight aluminum.

Outcome: Students lathed turbine blades, analyzed aerodynamics, and tested efficiency.

Skills Gained: CAD design, machining, data analysis, and collaborative problem-solving.

This project exemplifies how mini lathes turn abstract STEM theories into tangible, memorable experiences.

As schools prioritize 21st-century skills, mini lathes and CNC lathes will become classroom staples. Emerging trends include:

AI Integration: Smart lathes that offer real-time feedback on student projects.

Virtual Hybrid Labs: Combining physical machining with AR/VR simulations.

Sustainability Focus: Teaching circular economy principles by repurposing scrap materials.

The purpose of a lathe machine transcends manufacturing—it’s a catalyst for innovation and education. By bringing mini lathes into STEM programs, educators equip students with technical prowess, creativity, and confidence to tackle real-world challenges. At Xendoll Tools, we’re proud to support this mission with reliable, accessible machines tailored for tomorrow’s engineers.

Whether you’re a teacher, hobbyist, or distributor, explore how our mini CNC lathes can transform learning spaces at xendolltools.com. Together, let’s shape the future—one student, and one project, at a time.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options