Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Aug 22, 2025

Aug 22, 2025

950

950

The world of manufacturing, prototyping, and hobbyist machining is built upon a foundation of machine tools. These are the power-driven devices that shape, cut, form, and manipulate metal, wood, and other materials into precise components. For mechanical distributors, educational institutions, and machining enthusiasts, understanding the core types of machine tools is essential. It's the first step in selecting the right equipment for any task, whether it's building a custom motorcycle part or teaching the fundamentals of mechanical engineering. This guide will break down the primary categories of machine tools, explaining their unique functions and applications, and highlight how modern miniaturized versions are making this technology more accessible than ever.

While there are countless specialized machines, most fall into a few fundamental categories based on their primary cutting action and purpose.

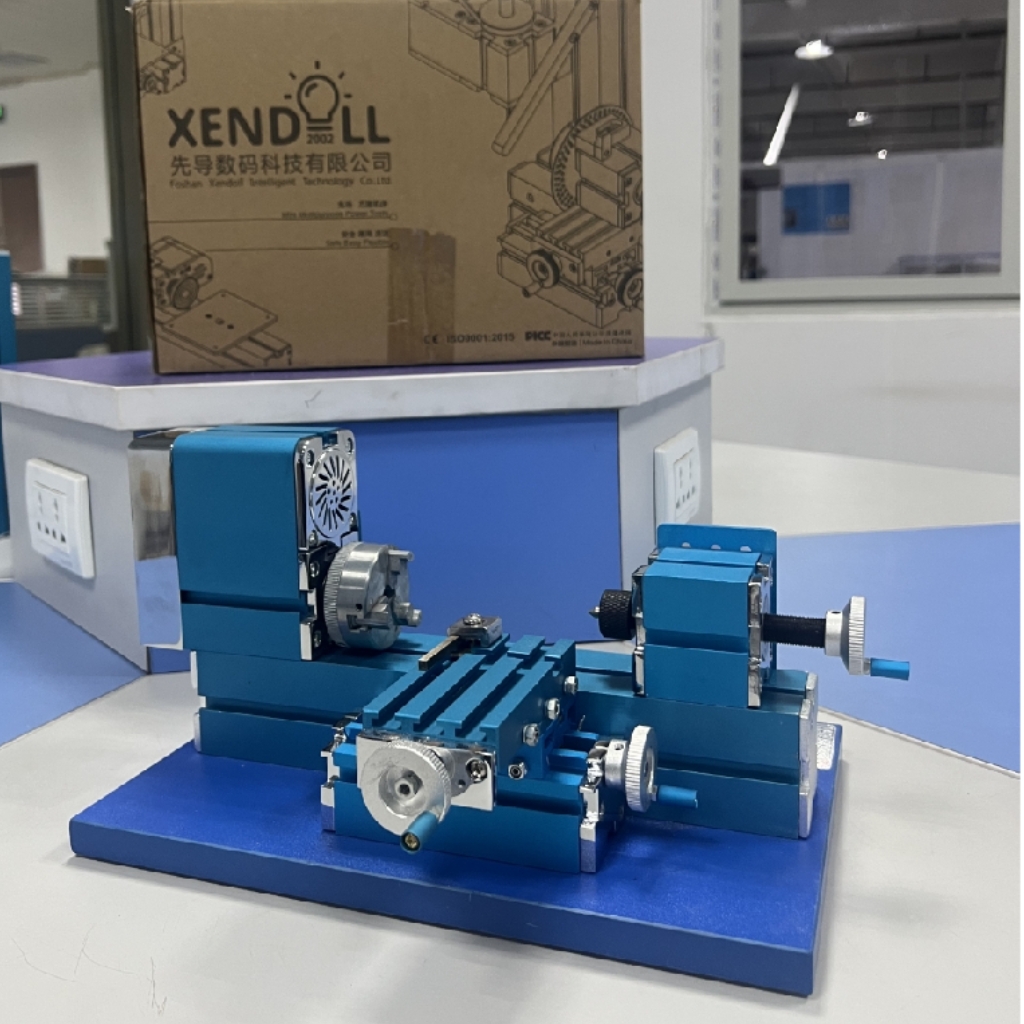

The lathe is arguably the oldest and most fundamental machine tool. Its principle is simple: the workpiece is rotated at high speed while a stationary cutting tool is pressed against it to remove material. This process, known as "turning," is perfect for creating cylindrical or conical shapes.

Primary Operation: Turning, facing, threading, boring, and drilling.

Key Outputs: Shafts, bolts, pulleys, baseball bats, and table legs.

Xendoll Context: Our mini precision benchtop lathes are perfect for model engineers, clockmakers, and vocational schools, offering full functionality in a compact, safe, and affordable package for detailed work on small parts.

If a lathe rotates the workpiece, a milling machine does the opposite: it rotates a multi-toothed cutting tool while the workpiece remains stationary (or moves in a controlled path). This allows for an incredible variety of operations, from cutting flat surfaces and complex contours to drilling holes and cutting gears.

Primary Operation: Face milling, end milling, slot cutting, drilling, and tapping.

Key Outputs: Engine blocks, gears, brackets, molds, and intricate mechanical components.

Xendoll Context: A mini milling machine is indispensable for any serious hobbyist or R&D department. It’s ideal for creating precise parts from blocks of metal or plastic, making it a cornerstone tool for prototyping and custom projects.

As the name implies, drilling machines are designed primarily to create cylindrical holes. The most common type is the drill press, where a rotating drill bit is pressed vertically into a stationary workpiece. While milling machines can also drill, dedicated drill presses offer superior stability and accuracy for high-volume hole-making.

Primary Operation: Drilling, reaming, counterboring, and countersinking.

Key Outputs: Precisely located holes in parts for assembly.

Xendoll Context: A benchtop drill press is a fundamental tool for any workshop, ensuring holes are perfectly perpendicular and consistent, which is crucial for quality craftsmanship.

Grinding machines use a rotating abrasive wheel to remove a very small amount of material from a workpiece. Their primary purpose is not to shape a part but to achieve an extremely high-quality surface finish and very tight dimensional tolerances, often to within thousandths of a millimeter.

Primary Operation: Surface grinding, cylindrical grinding, and tool sharpening.

Key Outputs: Perfectly flat surfaces, precisely sized bearing races, and sharp cutting tools.

Xendoll Context: While more specialized, a mini surface grinder or tool and cutter grinder is vital for enthusiasts who need to sharpen their own milling bits or achieve a flawless finish on a critical component.

Before any turning or milling can begin, raw material (like bars, tubes, or sheets) must be cut to a rough length. This is the job of sawing machines, which include bandsaws and cold saws. They are the unsung heroes of the workshop, providing the blank canvas for all other machines.

Primary Operation: Cutting material to length.

Key Outputs: Billets and blanks of metal, plastic, or wood ready for machining.

Xendoll Context: A mini bandsaw is a safe and efficient way for hobbyists and small workshops to process stock material without relying on large, industrial suppliers.

It's impossible to discuss machine tools today without mentioning Computer Numerical Control (CNC). CNC is not a type of machine itself but a transformative technology that can be applied to almost any machine tool—lathes become CNC lathes, mills become CNC machining centers.

CNC machines are automated, following a programmed set of instructions (G-code) to move the tools and workpiece with incredible precision and repeatability. This technology has revolutionized manufacturing, enabling the production of highly complex parts with minimal human intervention and is a key feature of many modern mini machines for advanced hobbyists and professional prototyping.

From the rotating spindle of a lathe to the programmed precision of a CNC mill, each type of machine tool plays a distinct and vital role in the world of fabrication. Understanding these differences is key to building an efficient and capable workshop.

For our core audiences—overseas mechanical distributors, educational equipment dealers, and machining enthusiasts—this knowledge empowers you to make informed decisions. Whether you're stocking a showroom, equipping a classroom lab, or pursuing a personal passion project, the right machine tool unlocks limitless potential.

At Xendoll Tools, we specialize in bringing this potential to your benchtop. Our range of high-precision mini lathes, milling machines, and drill presses combines industrial principles with compact, user-friendly design. They are the perfect solution for education, small-part manufacturing, and the discerning hobbyist who demands professional results.

Ready to find the perfect machine tool for your application? Explore our full catalog of high-quality, precision mini machine tools at xendolltools.com and take your projects to the next level.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options