Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Aug 21, 2025

Aug 21, 2025

987

987

The manufacturing world is undergoing a radical transformation, driven by the relentless march of automation, robotics, and AI. In this high-tech landscape, one might wonder about the fate of foundational machine tools like the lathe. Is the centuries-old lathe machine becoming obsolete? The answer is a definitive no. Rather than being replaced, the lathe is being reinvented and recontextualized. The future of lathe machines isn't about disappearance; it's about integration, accessibility, and specialization. For mechanical distributors, educational equipment suppliers, and machining enthusiasts, understanding this shift is key to unlocking new opportunities. Companies like Xendoll Tools, providing high-precision mini lathes, are at the heart of this new, dynamic ecosystem.

The lathe's evolution is being shaped by several interconnected trends that ensure its relevance for decades to come.

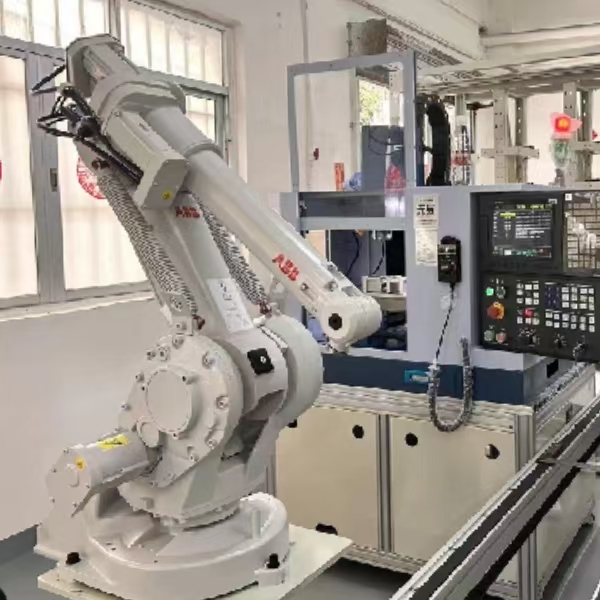

1. Integration with CNC and Automation: The Rise of the Hybrid Workshop

The most significant trend is the seamless integration of traditional manual lathes with Computer Numerical Control (CNC) technology. While fully automated CNC lathes dominate high-volume production, they haven't erased the need for manual skill.

The Prototyping and Small-Batch Niche: For creating a single prototype, performing a quick modification, or producing a small batch of parts, setting up a massive CNC system is often time-consuming and economically unviable. A skilled machinist using a precision manual lathe can often complete the job faster and more cost-effectively. This makes robust mini lathes indispensable in R&D departments, repair shops, and job shops that value flexibility.

The Training Pathway: CNC programming doesn't replace fundamental machining knowledge; it builds upon it. Operators must understand speeds, feeds, tool geometry, and material properties—skills best learned on a manual machine. This creates a massive demand for quality training lathes in vocational schools and universities, a core market for educational equipment distributors.

2. The Democratization of Machining: Empowering Hobbyists and Makers

Automation has driven down the cost of technology, making advanced tools more accessible than ever. The maker movement and the growth of home-based precision machining are thriving.

Desktop Manufacturing: Enthusiasts, model engineers, watchmakers, and custom automotive restorers are a growing market. They don't need industrial-scale automation; they need reliable, accurate, and affordable mini lathes to bring their creative visions to life. This community values the hands-on experience and the meditative, skilled craft of turning metal, a stark contrast to simply pressing a "start" button.

Tooling and Accessories: This boom creates a secondary market for high-quality tooling, chucks, and accessories. Distributors who cater to this passionate audience with reliable equipment like that from Xendoll Tools position themselves for long-term success.

3. Enhanced Precision and Smart Features

The future lathe, even at the mini and benchtop level, is getting smarter. While not fully automated, these machines are incorporating technology to enhance usability and results.

Digital Readouts (DROs): Adding a DRO to a manual lathe drastically improves accuracy and reduces errors by providing precise digital measurements of carriage and cross-slide position. This bridges the gap between pure manual operation and full CNC.

Variable Speed Control and Improved Ergonomics: Modern lathes feature electronic variable speed control for smoother operation and safety. Better materials, castings, and designs lead to more rigid and vibration-free machines, directly improving finish quality and the ability to work with tougher materials.

4. Sustainability and Custom Repair

In an era focused on sustainability, the ability to repair and create custom parts is invaluable. Instead of discarding a broken appliance or vintage machine, a hobbyist or local machinist can use a lathe to fabricate a replacement component that is no longer available. This circular economy approach, powered by precise miniature machine tools, reduces waste and preserves functionality, adding a new layer of practical value to lathe ownership.

So, what is the future of the lathe machine in the age of automation? It is bright, nuanced, and essential. The narrative is not one of replacement but of symbiosis. High-volume, lights-out factories will continue to rely on advanced CNC turning centers, while the world of innovation, education, customization, and craft will be powered by modern, precise manual and hybrid lathes.

The value of understanding material behavior through hands-on operation cannot be automated away. It is the foundation upon which automation is built. For mechanical dealers, this means stocking versatile machines that serve both training and specialized professional needs. For educational equipment distributors, it highlights the critical importance of providing students with high-quality tools to build foundational skills. And for the machining enthusiast, it signifies that their craft is more relevant than ever, supported by better, more accessible technology.

The future of machining is not a choice between manual and automatic; it's about having the right tool for the right job. Xendoll Tools is committed to being that right tool—providing the precision, reliability, and performance that professionals, educators, and hobbyists need to build, create, and innovate in this new era.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options