Blog

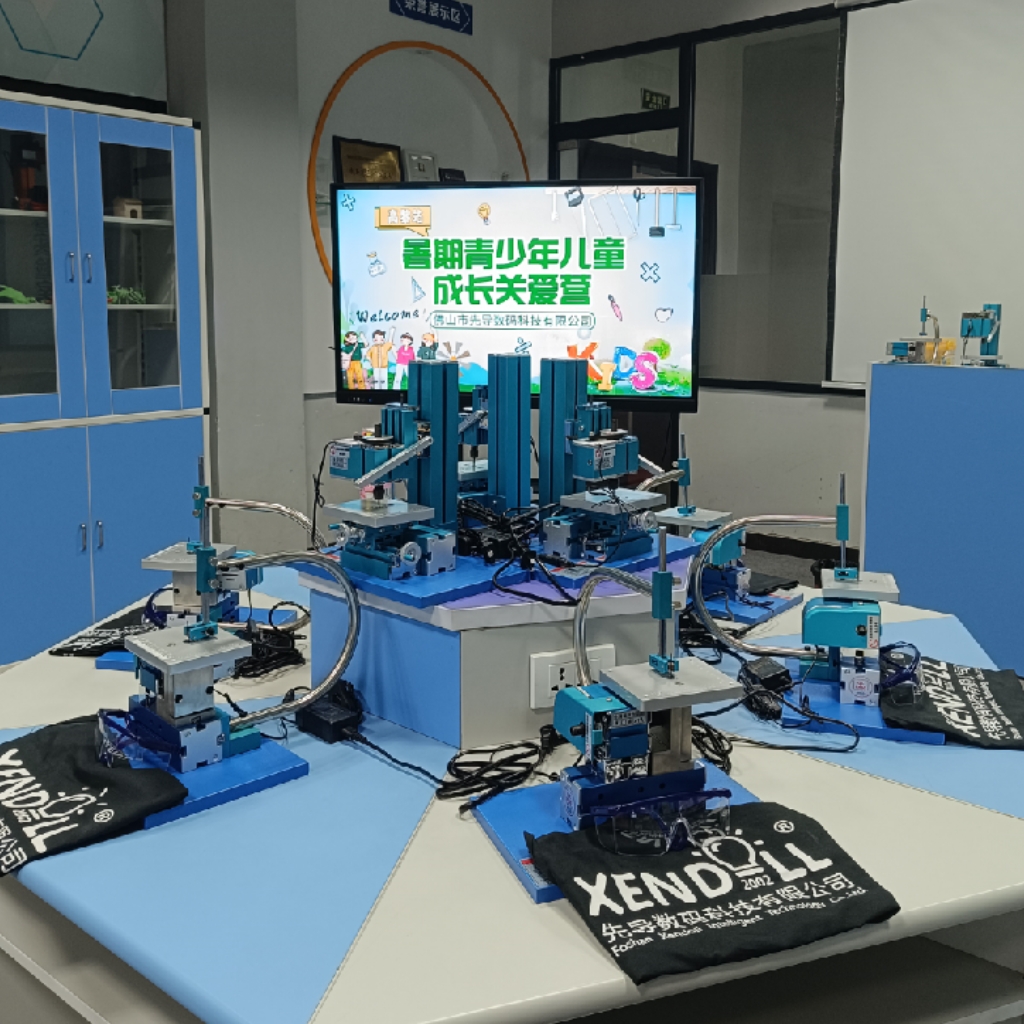

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jul 22, 2025

Jul 22, 2025

1100

1100

That unsettling sight – your workpiece mounted securely, the lathe spindle engaged, yet instead of smooth, concentric rotation, you witness a pronounced wobble. This phenomenon, known as runout, isn't merely an aesthetic concern. It compromises dimensional accuracy, mars surface finishes, accelerates tool wear, and can even pose safety hazards. For machinists, educators, and hobbyists alike, conquering runout is fundamental to precision turning. This guide systematically explores the root causes and effective remedies to achieve perfectly stable workpiece rotation.

I. Troubleshooting Chuck Imperfections (The Common Culprit)

The chuck frequently lies at the heart of runout issues.

Contamination is the Enemy: Microscopic debris – chips, grit, or burrs – trapped between chuck jaws, on the mounting face (backplate), or the spindle nose can induce significant wobble. Action: Diligently clean all contact surfaces (jaws, workpiece, chuck body, spindle nose) using appropriate brushes and solvents before assembly.

Jaw Management: Jaws tightened unevenly or not fully seated in their scroll can distort the workpiece position. Practice: Tighten jaws progressively and uniformly using a star pattern (opposite jaws). For critical centering, especially on non-round stock, an independent 4-jaw chuck offers superior adjustability.

Chuck Wear & Precision: Over time, chucks degrade. Jaw bores distort, scroll mechanisms wear, and mounting surfaces damage. Diagnosis: Mount a dial indicator on the tool post and measure runout directly on the chuck body during manual spindle rotation. Significant deviation indicates wear. Consider professional refurbishment or investing in a new, high-precision chuck – a key upgrade for mini-lathes seeking optimal performance.

Secure Attachment: A loosely mounted chuck guarantees instability. Essential: Verify the chuck is firmly locked onto the spindle nose according to your lathe's specific system (e.g., camlock pins engaged, threaded connection tight).

II. Rectifying Workpiece & Holding Issues

The material itself or insufficient support often contributes to the problem.

Material Flaws: Bent, warped, or irregular stock (common in thin bar or cut-offs) will inherently exhibit runout. Strategy: Select the straightest material available. For precision tasks, machine a true cylindrical section within the chuck first, then re-grip on this newly machined surface. Utilize tailstock center support for longer pieces to drastically enhance stability.

Inadequate Holding Power: Gripping a workpiece with insufficient length inside the jaws undermines rigidity. Guideline: Ensure chuck engagement length is typically at least 1.5 times the workpiece diameter. Always employ the tailstock center for slender or extended components.

Poor Gripping Surfaces: Attempting to hold onto rough, uneven, or tapered surfaces invites inaccuracy. Preparation: Prior to final machining, create a clean, cylindrical, and square-faced section specifically designed for the chuck jaws to grip securely.

III. Enhancing Setup Stability

Optimizing lathe configuration is vital for eliminating vibration.

Tailstock Misalignment: If the tailstock center isn't horizontally aligned with the spindle axis, it forces the workpiece to bend, causing runout along its length. Critical Step: Precisely align the tailstock using test bars and dial indicators, following your lathe's manual. Essential for long-part turning.

Center Maintenance: A damaged, dirty, or unlubricated dead center (or malfunctioning live center) creates friction and wobble. Care: Regularly inspect centers for damage. Keep them clean. Apply suitable high-pressure lubricant to dead centers. Ensure live centers rotate smoothly without play.

External Support Needs: Chuck and tailstock alone cannot prevent deflection in very long or thin workpieces under cutting forces. Solution: Correctly deploy a steady rest (stationary support) or follower rest (moving support) to counteract bending, which manifests as wobble.

IV. Assessing the Lathe Itself (Less Likely, But Possible)

Machine integrity, though rarely the primary cause, should be considered if other fixes fail.

Spindle Bearing Condition: Worn or damaged spindle bearings introduce inherent runout. Inspection: Measure runout directly at the spindle nose using a precision test bar held tightly in the chuck. Significant deviation necessitates professional bearing service.

Machine Foundation & Level: A lathe resting on an unstable or twisted bed transmits vibrations and can affect overall alignment. Foundation Check: Ensure the lathe is accurately leveled on a solid, vibration-absorbing base using a precision level.

V. Precision Tools for Reliable Results: The Xendoll Difference

While meticulous technique is paramount, the inherent stability of your mini metal lathe profoundly impacts your ability to consistently achieve true rotation. Xendoll machines are engineered to minimize runout:

Optimized Construction: Dense castings and precise machining reduce vibration and deflection during operation.

High-Grade Spindles: Quality bearings and accurately machined spindles provide a low-runout foundation.

Enhanced Chuck Integration: Designed for compatibility with precision chucks, ensuring optimal grip and centering capability.

Simplified Alignment: Features promoting easier and more reliable tailstock setup contribute to overall workpiece stability.

Conclusion: Mastering Stability for Precision Turning

Conquering wobble on a metal lathe is achieved through systematic diagnosis and precise execution. Begin with thorough cleaning and inspection of the chuck and workpiece surfaces. Guarantee sufficient grip length and leverage tailstock support consistently. For extended parts, meticulously align the tailstock and maintain centers. Select quality stock and prepare effective gripping surfaces. Consider machine health only after ruling out setup and holding issues.

By understanding these principles and applying the solutions diligently, you transform erratic wobble into the smooth, concentric rotation essential for professional machining outcomes. Whether you're a hobbyist pursuing perfection, an educator demonstrating precision, or a distributor supplying reliable tools, a well-configured lathe – particularly a stable platform like a Xendoll mini-lathe – is the cornerstone of machining success. Move beyond battling runout and embrace the accuracy your projects demand.

For details, please refer to the following link:

https://www.xendolltools.com/category/micro-cnc-machine.html

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options