Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jul 11, 2025

Jul 11, 2025

1106

1106

CNC (Computer Numerical Control) technology has transformed precision manufacturing, hobbyist workshops, and educational programs globally. Whether you're a mechanical distributor, educational supplier, or machining enthusiast, grasping the diversity of CNC machines is essential. While there's no single answer to "how many types exist," they are broadly classified by their core operation and purpose. This guide demystifies the primary CNC categories, showcasing their distinct roles and ideal users.

Core CNC Machine Categories Explained

CNC Milling Machines:

Core Action: Utilize rotating cutters to carve material from a stationary workpiece, handling tasks like drilling, contouring, and slotting.

Common Configurations: Vertical Machining Centers (VMCs), Horizontal Machining Centers (HMCs), plus 3-axis, 4-axis (rotary), and 5-axis (multi-directional) models. Bed Mills and Turret Mills are also prevalent.

Typical Scenarios: Fabricating intricate components like engine parts, molds, or custom brackets. Compact CNC mills are particularly valued by hobbyists and educators for prototyping and small-batch production.

CNC Lathes (Turning Centers):

Core Action: Rotate the workpiece against fixed tools to produce cylindrical shapes, performing facing, turning, threading, and parting operations.

Common Configurations: Standard 2-axis lathes, Multi-axis models with live tooling ("mill-turn"), and specialized Swiss-types for ultra-precision small parts.

Typical Scenarios: Crafting rotationally symmetric items such as shafts, bushings, and pulleys, crucial for both precision workshops and volume production.

CNC Routers:

Core Action: Employ gantry structures for faster, lighter cuts on larger workpieces, primarily in softer materials (wood, plastic, foam, soft metals).

Common Configurations: Widely available in 3-axis to 5-axis formats, often featuring expansive work areas. Benchtop CNC routers are fundamental for hobbyists, woodworkers, sign makers, and schools due to their adaptability and ease of use.

Typical Scenarios: Creating signage, custom furniture, engraved artwork, architectural models, and precise sheet material cutting.

CNC Plasma Cutters:

Core Action: Slice through conductive metals (steel, aluminum) using a high-velocity plasma jet.

Structure & Operation: Typically gantry-based systems moving a torch over flat stock, controlled via specialized 2D CAD/CAM software.

Typical Scenarios: Metal fabrication shops cutting shapes for frames, artwork, brackets, and structural elements from sheet or plate.

CNC Laser Cutters/Engravers:

Core Action: Focus a laser beam for cutting, engraving, or marking; CO2 for organics (wood, acrylic), fiber lasers for metals.

Common Configurations: Primarily 2D/3-axis systems, with power levels scaling from desktop to industrial. Small-format laser systems are popular in maker spaces and small enterprises.

Typical Scenarios: Producing intricate jewelry, detailed engravings (awards, personalization), custom stencils, and rapid prototypes.

CNC Electrical Discharge Machines (EDM):

Core Action: Shape conductive materials via controlled electrical sparks (erosion), ideal for ultra-hard metals or intricate internal features.

Main Forms: Wire EDM uses a thin wire to cut complex profiles; Sinker EDM employs shaped electrodes to create cavities or 3D forms.

Typical Scenarios: Manufacturing precision molds, dies, medical implants, and aerospace components requiring stress-free machining.

CNC Grinders:

Core Action: Achieve exceptional surface finishes and tight tolerances using abrasive wheels, removing minimal material.

Common Types: Surface, cylindrical (internal/external), centerless, and tool & cutter grinders.

Typical Scenarios: Finishing hardened parts, creating precise bearing surfaces, and sharpening tools for automotive and aerospace applications.

Specialized & Niche CNC Systems:

Press Brakes: Precisely form sheet metal bends.

Waterjet Cutters: Cut virtually any material (metal, stone, composites) using high-pressure abrasive water, ideal for heat-sensitive substances.

Tube/Pipe Benders: Create accurate bends in tubing for frameworks and fluid systems.

Hybrid/Additive Systems: Some advanced 3D printers incorporate CNC motion control.

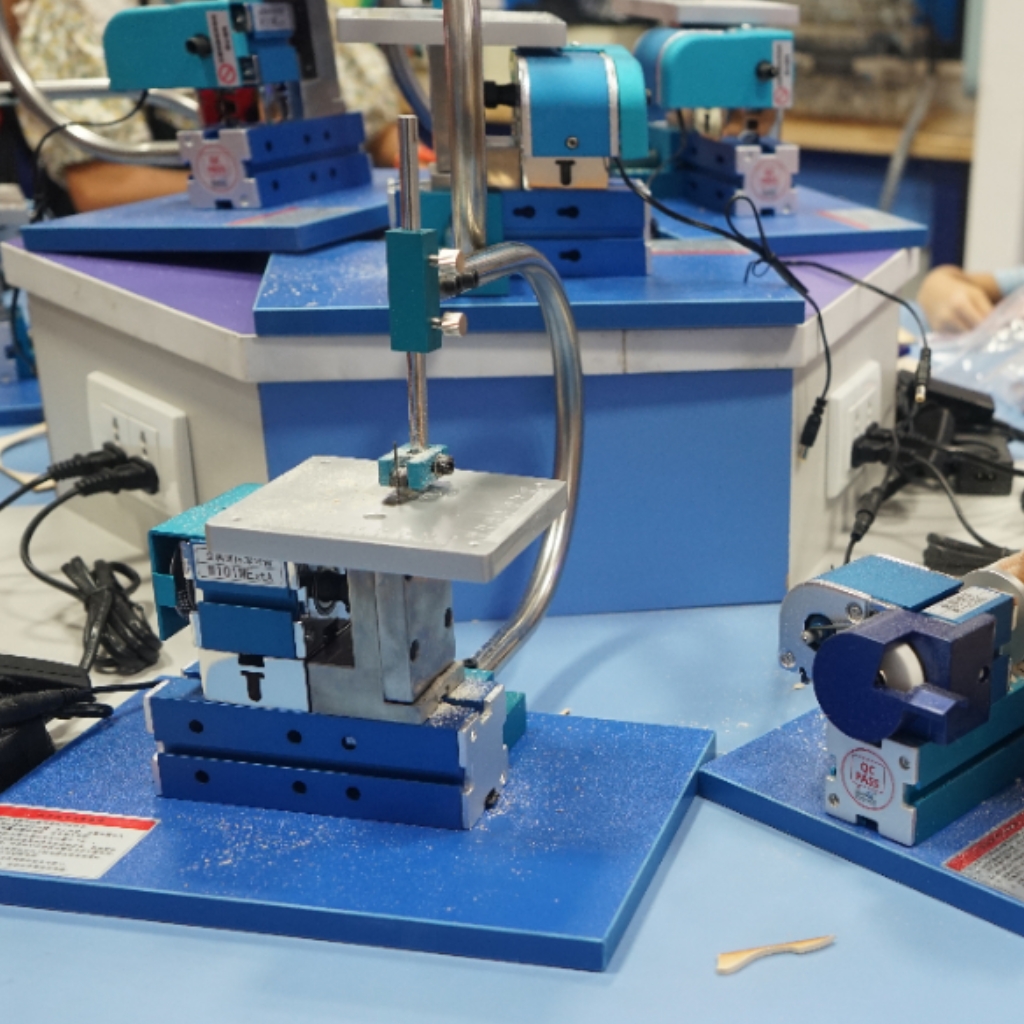

Why Compact CNC Machines Matter

Across key categories – especially Mills, Routers, Lathes, and Lasers – miniaturized CNC systems have revolutionized access, offering:

Lower Barriers: Reduced cost, space requirements, and power consumption versus industrial counterparts.

Broad Capability: Effectively work diverse materials (plastics, woods, soft metals) for custom parts, art, and prototypes.

Educational Power: Ideal for safely teaching CNC principles in schools, colleges, and training centers.

Empowerment: Enable hobbyists, artisans, and startups to achieve professional results affordably.

Conclusion: Matching Machine to Mission

While we've outlined eight fundamental CNC categories, the technology's landscape is dynamic and specialized. The critical question isn't just "how many types," but "which type best serves your specific material, part complexity, precision needs, and budget?"

For overseas mechanical distributors, educational equipment suppliers, and machining hobbyists, recognizing this spectrum is key. Space-efficient CNC solutions, particularly versatile mills and routers, represent a significant opportunity, delivering industrial-grade precision in accessible formats. Explore the potential CNC unlocks – high-accuracy manufacturing is now within reach for diverse users.

Unlock Precision Possibilities with Xendoll Tools: Your source for compact, powerful CNC solutions designed for enthusiasts, educators, and professionals globally. [Discover our CNC range at xendolltools.com]

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options