Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Sep 02, 2025

Sep 02, 2025

937

937

As the driving force behind contemporary production, Computer Numerical Control (CNC) technology enables the creation of highly precise parts across industries—from aerospace to custom automotive. For machining enthusiasts, educators, or future business owners, stepping into CNC may appear technically and financially challenging. Yet, with advancements in compact and affordable benchtop machines, entering this field has never been more feasible. This article outlines a clear pathway for beginning your CNC journey—whether you're looking to launch a startup, enrich technical education, or explore a new hobby.

A strong theoretical foundation is essential before operating any equipment.

Understand Key Terms and Methods: Familiarize yourself with fundamental principles such as G-code programming, toolpath strategies, material properties, and the differences between milling, turning, and engraving. Free online platforms—including instructional YouTube channels, specialized forums, and tutorial blogs—are excellent resources.

Master CAD/CAM Software: CNC production begins with digital design. Computer-Aided Design (CAD) programs help you model components, while Computer-Aided Manufacturing (CAM) software converts those models into machine-readable instructions. Beginners can start with accessible software such as Fusion 360, TinkerCAD, or Carbide Create.

Your machine and tools should align with your projects and goals.

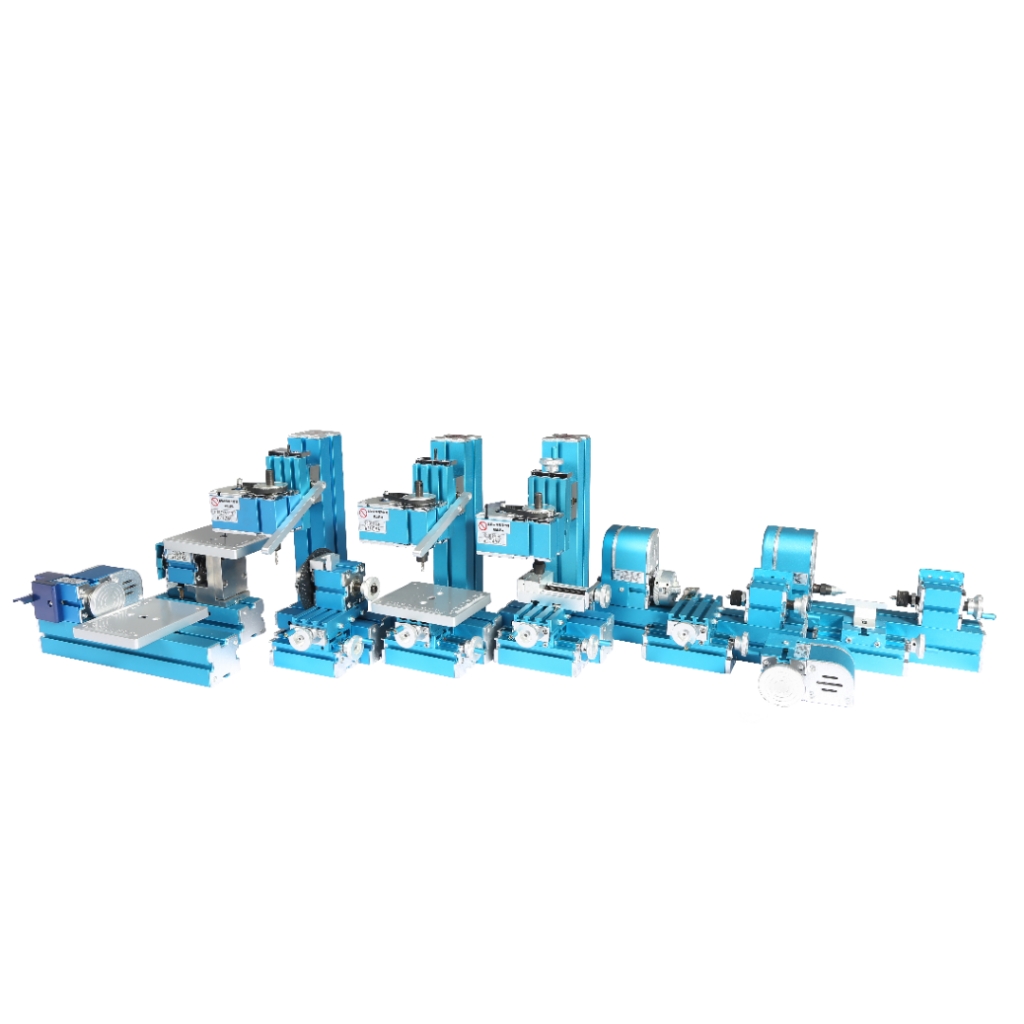

Choose a Machine That Fits: Desktop CNC routers and mills, such as those from Xendoll Tools, offer an ideal entry point. They are capable of handling woods, plastics, and non-ferrous metals like aluminum—perfect for prototyping, education, and personal projects.

Invest in Essential Tooling: Beyond the machine, you will need cutting tools (end mills, drills), workholding devices (vises, clamps), and critical safety gear. Accurate measurement tools like digital calipers are also indispensable for quality control.

Turning a idea into a physical part involves a streamlined digital process:

Design with CAD: Create a detailed 2D or 3D model of your object using CAD software.

Generate Toolpaths via CAM: Load your design into CAM software to define machining operations, select tools, set speeds and feeds, and simulate the cutting process.

Run the Program: Transfer the generated G-code to your CNC machine via USB or SD card, secure your material, and start the job. Always monitor early runs closely.

CNC machining is a skill improved through hands-on experience and community support.

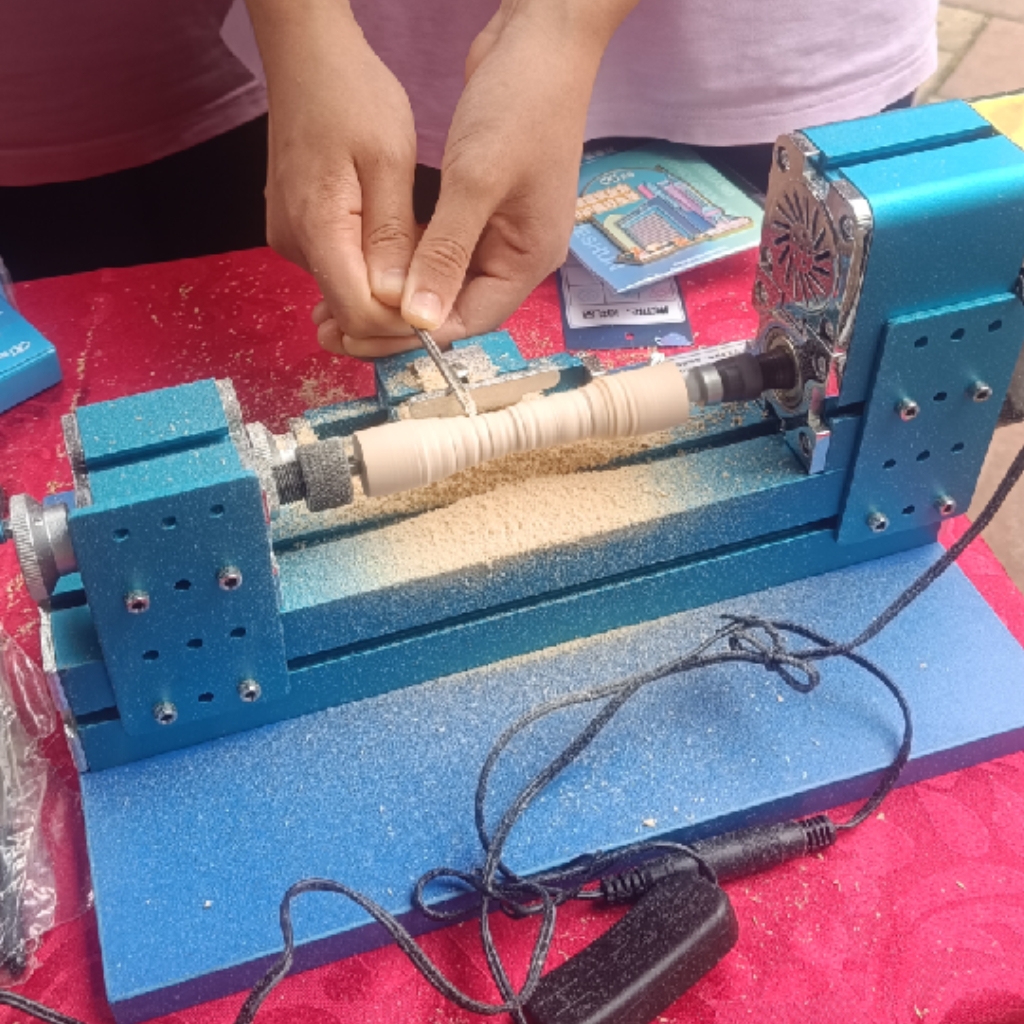

Start with Simple Projects: Begin with basic designs such as signs, simple enclosures, or tool organizers to build confidence and competence.

Test Various Materials: Experiment with different substrates—from plywood and acrylic to aluminum—to learn how cutting parameters affect results.

Connect with Other Makers: Join online groups, attend workshops, and participate in discussions to gain insights, troubleshoot issues, and share knowledge.

Starting in CNC manufacturing is an exciting process of combining creativity with technical skill. By learning foundational concepts, selecting suitable equipment—such as reliable benchtop machines from Xendoll Tools—and mastering the digital design workflow, you can effectively begin your journey. Remember that every expert was once a beginner: practice consistently, stay curious, and leverage community knowledge. There has never been a better time to transform your ideas into reality with CNC technology.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options