Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Dec 02, 2025

Dec 02, 2025

395

395

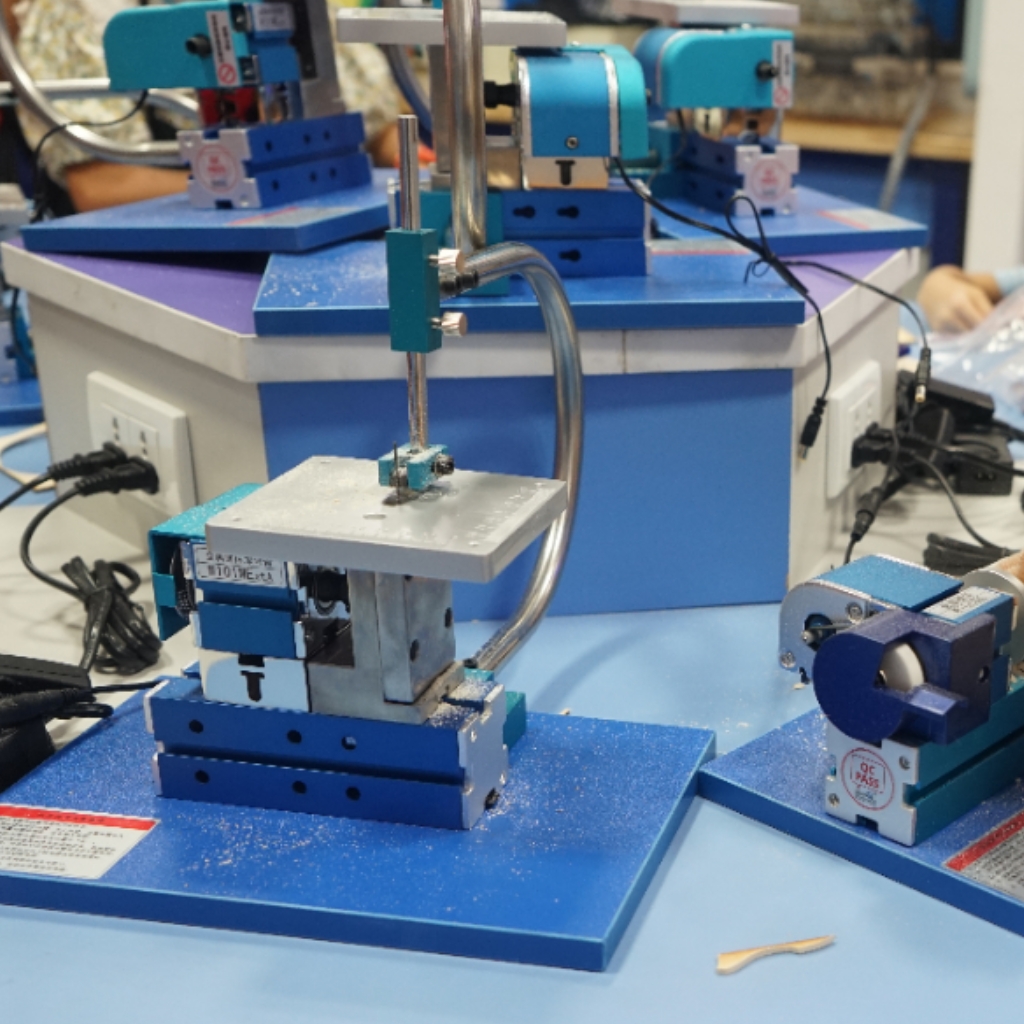

The world of machining and creation is at your fingertips. For engineers, makers, educators, and hobbyists, the desire to turn raw materials into precise, functional, or beautiful objects is a powerful drive. While full-scale industrial equipment remains out of reach for most workshops, the mini lathe stands as the perfect gateway to this universe of precision. More than just a scaled-down tool, a modern mini lathe is a powerful, capable, and accessible centerpiece for any small-scale fabrication project. If you’re contemplating bringing this capability into your space, you’re likely asking the right questions: What can it truly do? How do I choose the right one? This guide will walk you through the essentials of starting your journey with a new mini lathe.

The Core Advantages of a Modern Mini Lathe

Today's mini lathes are engineering marvels that pack significant potential into a compact footprint. Their primary advantage is accessibility. They bring the fundamental principles of turning—shaping material by rotating it against a cutting tool—to benchtops, garages, classrooms, and small studios without requiring industrial-scale space or power. This makes them ideal for a vast range of applications, from crafting precise components for model engineering and prototyping custom parts for repairs to creating unique pens, instruments, or jewelry.

Beyond size, the precision offered by a quality mini lathe is remarkable. With adjustable speeds, accurate chucks, and stable beds, they allow for work with metals like aluminum and brass, plastics, and woods to tolerances that satisfy even demanding hobbyists and educational curricula. Furthermore, they serve as an excellent educational platform. For students or newcomers, operating a mini lathe builds foundational skills in machining, mechanics, and tool handling in a manageable and safer environment compared to larger machinery.

Choosing Your Perfect Mini Lathe: A Practical Guide

Selecting the right machine is crucial for satisfaction and success. Your choice should hinge on three key pillars: Project Scope, Machine Specifications, and Brand Reliability.

First, define your primary projects. Are you focusing on delicate clock parts, sturdy model steam engine cylinders, or primarily wooden turnings? The material and finished size of your typical workpiece will directly dictate the required swing over bed (the maximum diameter of material that can rotate) and distance between centers (the maximum length of workpiece). A model maker might prioritize precision for small brass parts, while a guitar maker might need a longer bed for turning tool handles.

Next, scrutinize the specifications. Motor power (often 350W to 750W in this class) determines the machine's ability to handle tougher materials and deeper cuts without stalling. A variable speed control is highly recommended for versatility across different materials. Spindle thread and taper (like MT2 or MT3) are critical as they define the compatibility with chucks, centers, and other essential accessories. Don’t overlook build quality: a cast-iron bed offers superior vibration damping and rigidity over lighter materials, directly impacting finish quality.

Finally, invest in trust and support. Choose a reputable supplier known for consistent quality and good customer service. A reliable brand ensures better machining tolerances from the factory, availability of spare parts, and technical support. Consider what is included in the package; a basic set of tools, a faceplate, and centers can get you started immediately.

Beyond the Machine: Budgeting for a Complete Setup

The initial cost of the lathe itself is just part of the equation. A successful workshop requires essential accessories. You will need a set of cutting tools (HSS or carbide), a sharpening system for HSS tools, measuring devices (calipers, micrometers), and safety equipment like goggles. Planning for these additional items from the start prevents frustration and ensures you can operate effectively and safely.

Furthermore, think about your workshop infrastructure. A mini lathe needs a solid, level, and sturdy bench to mount on. Good, adjustable lighting is non-negotiable for precision work. You’ll also need to plan for material sourcing, chip management, and perhaps a small coolant system for metalworking.

Your Journey in Precision Begins Here

Embarking on the path with a new mini lathe opens a door to immense creative and practical potential. It transforms ideas in metal, plastic, and wood into tangible reality, fostering skill, patience, and accomplishment. By carefully considering your intended use, understanding the key specifications that matter, and planning for the complete setup, you can make an informed investment that will serve your passion for years to come.

Ready to explore the specific models and features that can turn your projects into reality? Visit xendolltools.com to discover our range of precision-engineered mini lathes and tooling, designed to meet the demands of discerning makers, workshops, and educational institutions worldwide. Start your precision turning journey with the right foundation.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options