Blog

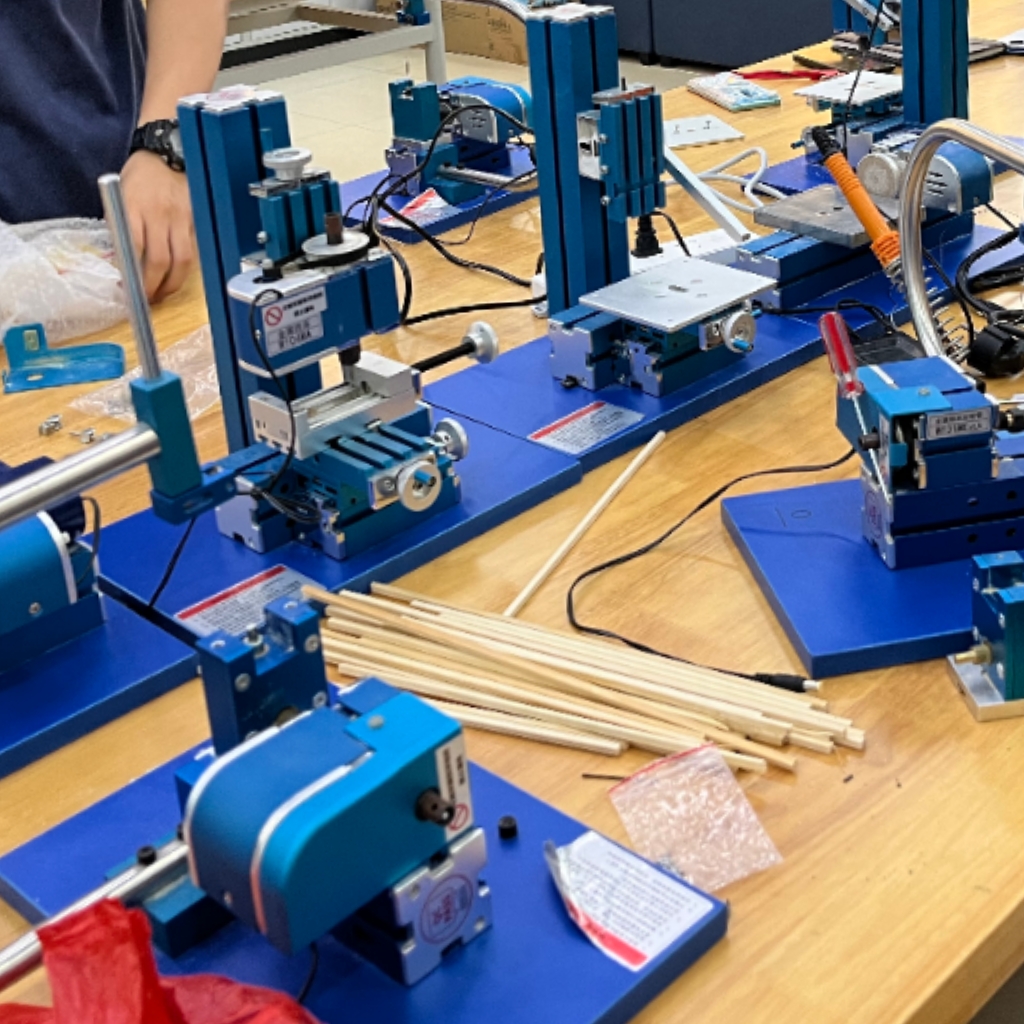

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jun 15, 2025

Jun 15, 2025

1122

1122

Transforming raw timber into functional art on the lathe defines woodturning. Knowing the essential operations empowers machining enthusiasts, educators sourcing equipment, and dealers serving the professional and educational markets.This guide outlines the fundamental techniques performed on a wood turning lathe.

Foundational Operations: Shaping the Basics

These operations establish the primary form and dimensions of the workpiece:

Facing Off: This is the first step when mounting wood between centers. It involves cutting or sanding the end grain square and smooth to the lathe's axis. This creates a crucial flat reference surface perpendicular to the lathe bed, ensuring the workpiece runs true for accurate subsequent work. Tools used include a roughing gouge, skew chisel (carefully), or sanding block.

Parallel Turning (Cylindering): This reduces a section of the spinning workpiece to a consistent, uniform diameter, creating a cylinder. It's the starting point for items like tool handles or table legs. Using a roughing gouge or spindle gouge, the turner makes controlled cuts along the workpiece length, removing material evenly until the desired diameter is achieved, constantly checking with calipers.

Taper Turning: This creates a gradual, uniform reduction in diameter along a cylindrical section, resulting in a conical shape. It's done similarly to parallel turning but requires a controlled, angled cut, guiding the tool gradually away from or towards the workpiece centerline. Common for decorative elements or handles, using spindle gouges or skew chisels.

Shoulder Cuts (Squaring Shoulders): This creates a sharp, clean 90-degree transition between two diameters or at the end of a tenon, defining distinct sections. Precise tool presentation is vital. A parting tool, skew chisel (point or heel cut), or spindle gouge is carefully brought into the wood at the exact shoulder point, cutting straight down. A rigid lathe minimizes chatter for clean shoulders.

Defining Features: Beads, Coves, and Profiles

These operations add detail and visual interest to the basic form:

Bead Cutting: This creates a rounded, convex shape protruding from the surface. Using a spindle gouge or bead-forming tool, the turner makes small, controlled scooping cuts, typically starting from the sides and meeting at the center. Precision is key for symmetrical beads.

Cove Cutting: This creates a concave, rounded groove or depression in the surface. Using a spindle gouge or bowl gouge (for larger coves), the turner makes a controlled sweeping cut into the wood, moving laterally while maintaining consistent depth and curve shape. Smooth tool travel is essential.

Separation and Precision: Parting & Drilling

These operations finalize forms or create functional elements:

Parting Off: This severs the finished workpiece from the waste wood held in the lathe. Using a narrow parting tool, the turner carefully cuts radially into the wood at the separation point, gradually deepening the cut until detachment. Control and lathe stability are critical to avoid breakage.

Drilling & Boring: This creates holes along the axis of the spinning workpiece. Drill bits (small holes) or specialized boring tools (larger holes) are mounted in the tailstock quill and advanced steadily into the rotating piece. Essential for lamp sockets, hollow forms, or functional holes. A robust tailstock with a smooth feed mechanism ensures accuracy.

Advanced Techniques: Expanding Possibilities

As skills progress, turners explore more complex operations:

Hollowing: Removing material from the inside (e.g., for bowls or vessels) using gouges and scrapers.

Threading: Cutting screw threads onto spindle work for lids or joins.

Chasing: Cutting precise decorative threads, beads, or lines.

Burning/Texturing: Creating decorative patterns with heat or tools.

Sanding & Finishing: Critical final steps performed on the spinning workpiece (sanding smooth, applying oil, wax, or lacquer).

Conclusion: The Essential Craft of Woodturning

Mastering core wood lathe operations – facing, parallel turning, tapering, beads, coves, parting, and drilling – unlocks the potential to create items ranging from simple spindles to intricate decorative pieces. These techniques highlight the precision, versatility, and skill inherent in woodturning.

For overseas mechanical dealers, educational equipment suppliers, and dedicated machining enthusiasts, reliable equipment is fundamental to successfully performing these operations. XendollTools.com offers robust mini lathes and accessories designed for stability, control, and durability, meeting the demands of both fundamental techniques and advanced projects. Explore the range at xendolltools.com to find tools that empower craftsmanship or enhance your business offerings.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options