Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jul 02, 2025

Jul 02, 2025

1206

1206

Mini CNC machines are revolutionizing accessibility to precision manufacturing. No longer confined to industrial factories with massive budgets and floorspace, these compact powerhouses bring computer-controlled cutting, carving, and milling capabilities to workshops, classrooms, and even desktops worldwide. At Xendoll Tools, we specialize in providing high-quality mini CNC solutions for diverse users. But what exactly are these versatile machines used for? Let's explore the wide-ranging applications driving their popularity.

I. Empowering Hobbyists and Makers: Precision at the Personal Level

For the passionate home machinist, model builder, artist, or tinkerer, mini CNC machines unlock a world of creative and functional possibilities:

Intricate Crafting & Artwork: Create stunningly detailed engravings on wood, acrylic, leather, and soft metals. Produce custom signs, personalized gifts, decorative panels, and intricate jewelry pieces with precision impossible by hand.

Precision Model Making: Fabricate accurate components for scale models (trains, planes, RC vehicles, architectural models) from balsa, plastics, and light metals. Achieve perfect fits and complex geometries consistently.

Custom Parts & Prototyping: Design and manufacture bespoke parts for repairs, upgrades to existing equipment, or unique projects. Quickly prototype functional components before committing to larger-scale production.

PCB Milling: Prototype electronic circuits by precisely milling away copper from blank boards to create custom Printed Circuit Boards (PCBs) for electronics projects.

Musical Instrument Components: Craft precise parts for guitars, violins, or other instruments, such as bridges, nuts, inlays, or even custom headstock designs.

The affordability, small footprint, and relative ease of use (especially with modern software) make mini CNCs the perfect workshop companion for bringing digital designs into tangible reality.

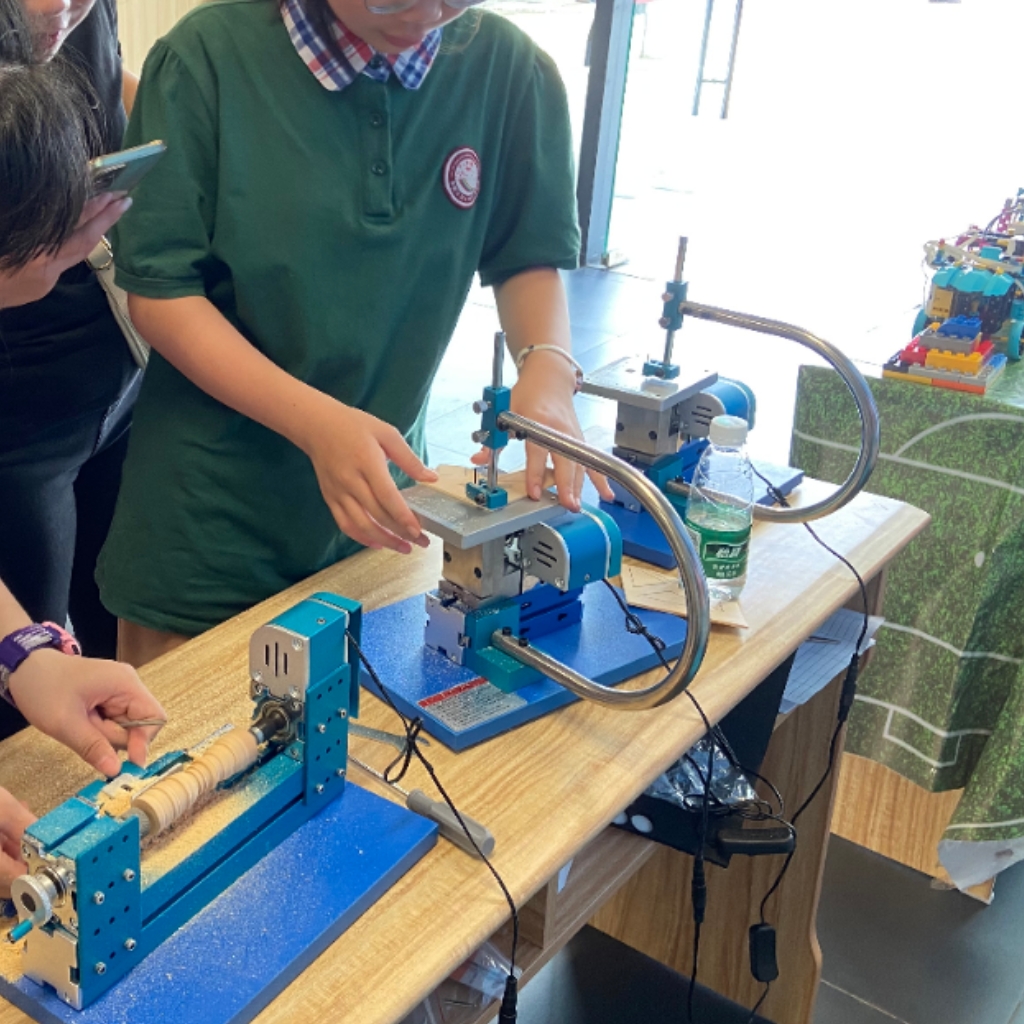

II. Transforming Education: Hands-On Learning for Future Innovators

Educational institutions, from high schools to universities and vocational training centers, increasingly leverage mini CNC machines as essential STEM/STEAM tools:

Teaching Core Engineering & Manufacturing Principles: Provide hands-on experience with Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), G-code programming, material properties, machining processes, and quality control – fundamental skills for engineering and technical careers.

Project-Based Learning: Enable students to design, prototype, and manufacture real projects, fostering critical thinking, problem-solving, and practical application of theoretical knowledge. Projects range from robotics parts to architectural models to functional mechanisms.

Developing Digital Fabrication Skills: Introduce students to the concepts of digital manufacturing and rapid prototyping, preparing them for careers in modern workshops, makerspaces, and advanced manufacturing environments.

Safe and Accessible Introduction: Mini CNCs offer a much safer and more manageable environment for students to learn machining fundamentals compared to large industrial equipment, while still delivering professional results. Their lower noise and space requirements make them ideal for classroom integration.

Xendoll Tools' reliable and user-friendly mini CNC machines are trusted by educational equipment distributors globally to equip the next generation of engineers and makers.

III. Serving Industry: Practical Solutions for Specialized Needs

While distinct from heavy industrial CNCs, mini CNC machines find valuable niches in professional settings, particularly benefiting small businesses, specialized workshops, and service providers:

Rapid Prototyping & Small Batch Production: Quickly produce functional prototypes or small runs of custom parts (e.g., jigs, fixtures, specialized components, replacement parts) cost-effectively without outsourcing. Ideal for R&D departments or small manufacturers.

Specialized Engraving & Personalization: Offer customized engraving services on a wide array of items – awards, trophies, promotional products, tools, equipment panels, and gifts – with high detail and repeatability.

Niche Manufacturing & Craft Production: Support artisans and small businesses in producing intricate components for jewelry, musical instruments, specialized crafts, or bespoke furniture elements.

Toolroom & Maintenance Applications: Machine precise custom tooling, jigs, fixtures, or repair parts on-demand, reducing downtime and reliance on external suppliers.

Low-Volume Customization: Provide tailored solutions for clients needing unique, small-scale modifications or personalized features on products.

For industrial equipment distributors, offering robust mini CNC solutions like those from Xendoll Tools addresses the growing demand for flexible, compact manufacturing capabilities across diverse sectors.

Conclusion: Versatility Compacted

Mini CNC machines are far more than just scaled-down industrial tools. They are versatile platforms democratizing precision manufacturing, enabling creativity, enhancing education, and providing practical solutions for specialized professional needs. Whether you're a hobbyist crafting intricate art, an educator shaping future engineers, a small business owner producing custom parts, or a distributor supplying these vital tools, the applications are vast and impactful.

Ready to explore how a mini CNC machine can unlock new possibilities for you or your customers? Discover the range of precision, reliable, and user-friendly mini CNC solutions designed for enthusiasts, educators, and professionals alike at Xendoll Tools: https://xendolltools.com. Find the perfect compact powerhouse to bring your ideas to life.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options