Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Sep 08, 2025

Sep 08, 2025

868

868

CNC manufacturing might seem like a domain reserved for industrial experts, but it’s now more accessible than ever. With the rise of compact, precision machines like those from Xendoll, enthusiasts, educators, and small businesses can explore this transformative technology. If you're wondering how to dive into CNC, this guide will walk you through the process—from building foundational knowledge to creating your first project.

Before investing in equipment, it’s essential to understand what CNC entails. Think of it as a blend of digital design and mechanical execution. Here’s what you need to know:

What Is CNC?

CNC, or Computer Numerical Control, is a subtractive manufacturing process. A machine carves out parts from solid blocks of material—such as wood, plastic, or metal—based on digital designs. Unlike 3D printing, which adds material layer by layer, CNC machining removes material with precision.

Key Components of CNC

A functional CNC setup involves software, hardware, and operational knowledge:

CAD Software: Used to design 2D or 3D models. Programs like TinkerCAD and Fusion 360 are great for beginners.

CAM Software: Translates designs into G-code, the language CNC machines understand. It defines toolpaths, speeds, and cutting depths.

The CNC Machine: The physical unit that executes the commands. For newcomers, a desktop CNC router offers an ideal balance of affordability and capability.

Controller Interface: Software that sends instructions to the machine and monitors its operation.

Theory alone won’t make you proficient. Here’s how to transition into practical work:

Start with Software

Begin by experimenting with CAD tools. Design simple objects like keychains or coasters to understand how sketches turn into三维 models. Many platforms offer free versions or trials, making it easy to learn without financial commitment.

Choose the Right Equipment

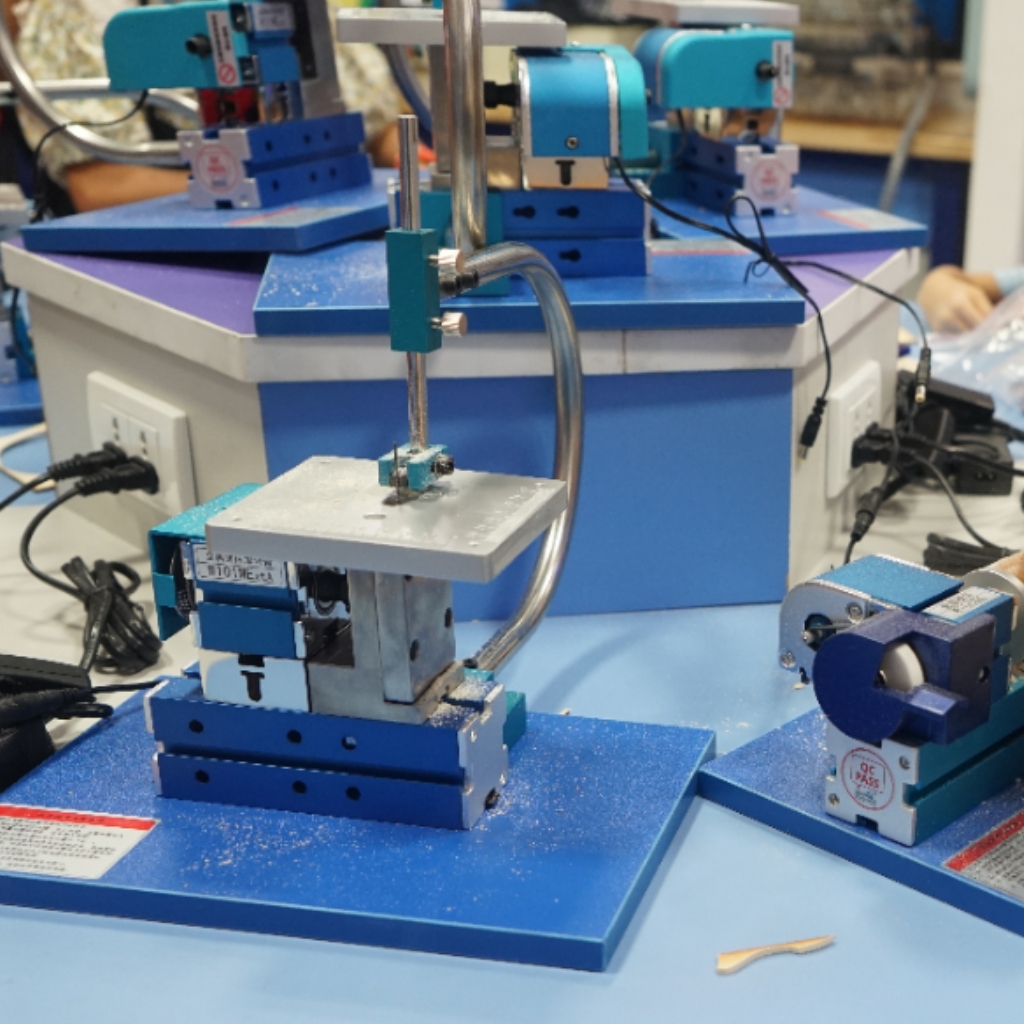

Your first machine should be user-friendly, reliable, and suited to your goals. Xendoll’s mini CNC machines are designed for beginners, offering precision, durability, and ease of use—perfect for working with woods, plastics, and soft metals.

Practice Core Techniques

Material Setup: Secure your workpiece firmly using clamps or adhesives to prevent movement during machining.

Tool Selection: Learn the differences between end mills—for example, use flat-end bits for sharp edges and ball-nose bits for curved surfaces.

Material Choices: Start with soft materials like wax, MDF, or pine to minimize errors and build confidence.

Execute a Simple Project

Begin with pre-designed files from online repositories. Focus on mastering machine operation: setting zero points, initiating jobs, and monitoring progress. This approach reduces pressure while building essential skills.

Every CNC practitioner encounters challenges early on. Here’s how to steer clear of frequent pitfalls:

Rushing Calibration: Incorrect tool alignment or inaccurate zero points can ruin a project. Double-check settings before starting.

Neglecting Safety: Always wear protective gear, including glasses and gloves. Keep your workspace tidy to avoid accidents.

Using Wrong Parameters: Improper feed rates or spindle speeds can damage tools or materials. Refer to manufacturer guidelines and adjust based on your material.

CNC manufacturing is an empowering skill that merges creativity with technical precision. By starting with a strong theoretical foundation, investing in accessible tools like Xendoll’s desktop CNC machines, and embracing hands-on practice, you can quickly progress from novice to confident creator.

The world of CNC is no longer limited to factories—it’s a hobby, an educational tool, and a gateway to innovation. Start designing, start machining, and unlock your potential to bring ideas to life.

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options