So, you're captivated by the world of CNC machining—the ability to turn digital designs into precise, physical objects. It's a powerful skill, opening doors to hobbies, careers, and entrepreneurial ventures. But one of the first questions that comes to mind is, "What is the investment required to learn CNC machining?"

The answer isn't a one-size-fits-all figure. The resources you'll need depend heavily on your chosen path, end goals, and the level of equipment you start with. The investment can range from a very accessible level for a hobbyist to a more significant commitment for professional-grade skills. Let's break down the key factors to give you a clear and realistic picture.

The Three Primary Pathways to Learning CNC

The biggest factor influencing your investment is how you choose to learn. There are three main avenues, each with a very different resource commitment.

1. Formal Education: The Structured, Comprehensive Route

This path includes technical colleges, trade schools, and university programs. It represents a significant investment of time and money but provides a deep, structured education and often leads directly to a career.

The Commitment: This option requires a substantial upfront investment and a dedicated time commitment for semesters or years of study.

Pros: Hands-on training on industrial machines, access to professional instructors, networking opportunities, and a formal credential that employers value.

Cons: High initial cost and a long-term time commitment.

2. On-the-Job Training: The Earning-While-Learning Model

Many people learn CNC machining by starting as an operator or apprentice in a machine shop. In this scenario, you are paid to learn.

Direct Financial Outlay: There is typically no direct cost to you for the training itself.

The Learning Dynamic: You will earn a salary while learning, but your training is dependent on the specific machines and processes your company uses. The learning curve is shaped by workplace needs.

Pros: No out-of-pocket cost for education, immediate income, and practical, real-world experience.

Cons: Less theoretical foundation; your learning scope may be limited to your employer's specific niche.

3. Self-Directed Learning: The Flexible, Hobbyist-Friendly Path

This is the most common and accessible route for DIY enthusiasts and home shop owners. You control the pace, depth, and budget.

Software: Many powerful CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software options have free or affordable versions for hobbyists. Professional licenses involve an ongoing subscription fee.

Training Resources: A wealth of information is available, from free online tutorials and forums to structured paid courses, allowing you to scale your knowledge investment.

The Central Investment: The Machine Itself. This is where companies like Xendoll Tools become a game-changer, offering equipment that makes the hardware investment manageable for learners.

Breaking Down the Equipment for the Self-Learner

For the DIY path, the CNC machine is your central investment. The market offers a tiered system to match every level of ambition.

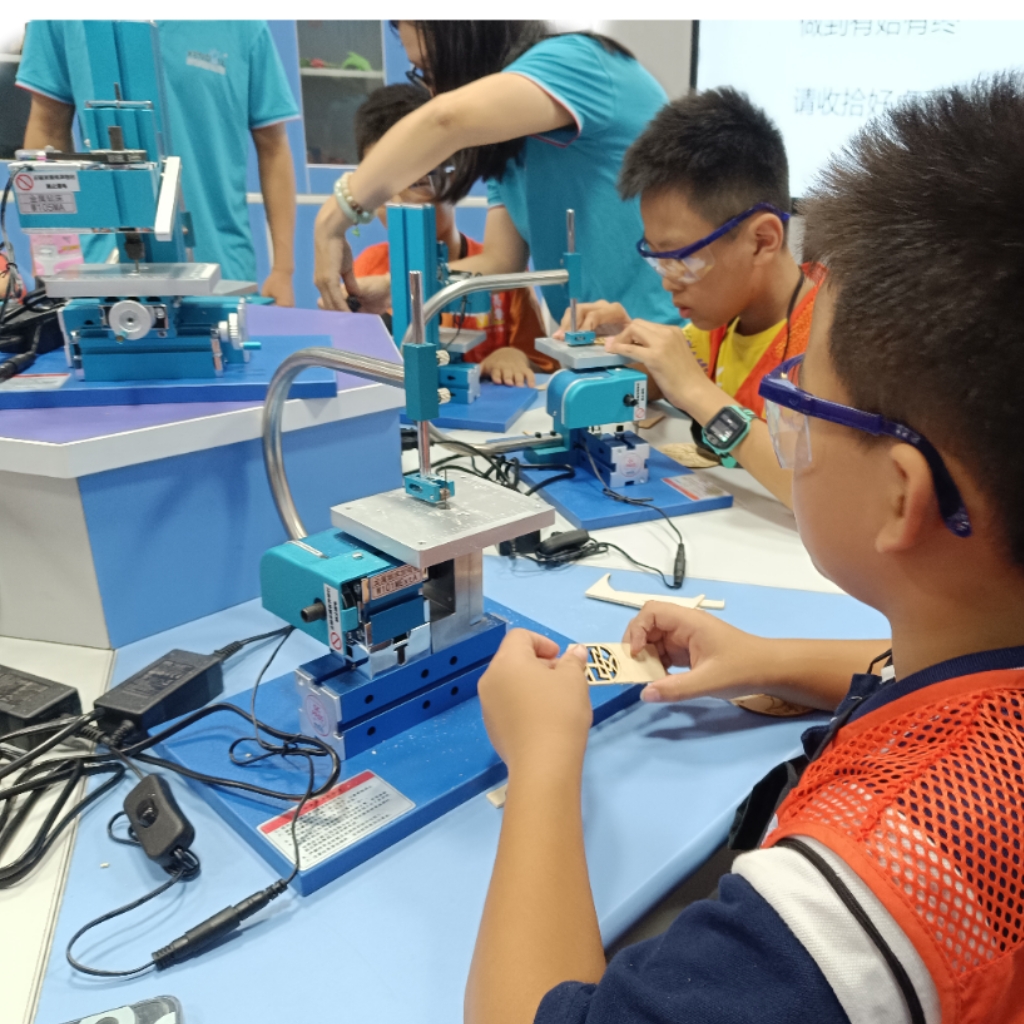

Desktop/Hobbyist CNC Machines: This is an accessible starting point. A reliable, high-quality mini CNC machine, like those from Xendoll Tools, is perfect for learning the fundamentals with materials like wood, plastics, and soft metals.

Benchtop CNC Mills: A step up in size, rigidity, and capability, these are for more serious hobbyists and small businesses.

Industrial CNC Machines: Used for professional production, these represent the highest level of investment for large-scale workshops.

Don't Forget Tooling and Materials!

Your initial machine investment is just the beginning. You must also account for:

Cutting Tools (End Mills, Drills): A starter set is essential for beginning projects.

Workholding (Vises, Clamps): Proper equipment to secure your material is crucial for safety and precision.

Raw Materials: You will need a supply of wood, aluminum, or plastic for practice and projects.

Conclusion: An Investment in Your Capability

So, what does it take to learn CNC machining? As we've seen, it's a spectrum of commitment.

For the career-focused individual, the formal education path is a major investment in time and money, treated as a foundational step for a professional career.

For the aspiring professional, on-the-job training requires no direct financial outlay and provides an income while building experience.

For the hobbyist and DIY maker, the self-directed path is highly flexible. With a strategic investment in a quality mini CNC machine from Xendoll Tools, coupled with free software and online resources, you can begin your hands-on journey with a manageable level of investment.

Ultimately, learning CNC machining is not just a purchase; it's an investment in a valuable skill, a creative outlet, or even a new business. By choosing the right path and the right equipment for your goals, you can effectively manage your resources. For those ready to start their hands-on journey, a reliable and well-supported mini CNC machine is the perfect launchpad to unlock the world of digital manufacturing.

Ready to start your CNC journey? Explore the range of precision mini CNC machines and accessories at Xendoll Tools designed specifically for learners, hobbyists, and small workshops. Find the perfect machine to fit your ambitions and bring your ideas to life.

Nov 13, 2025

Nov 13, 2025

495

495

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options