Features

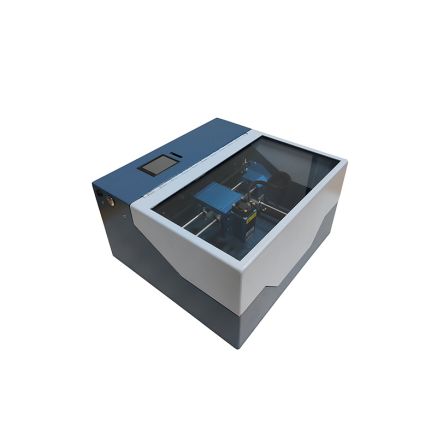

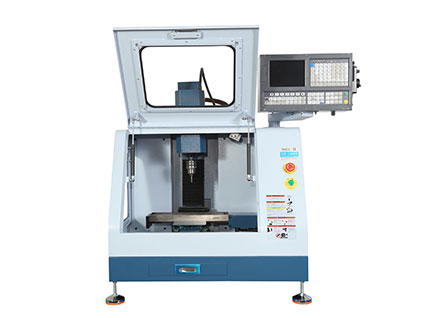

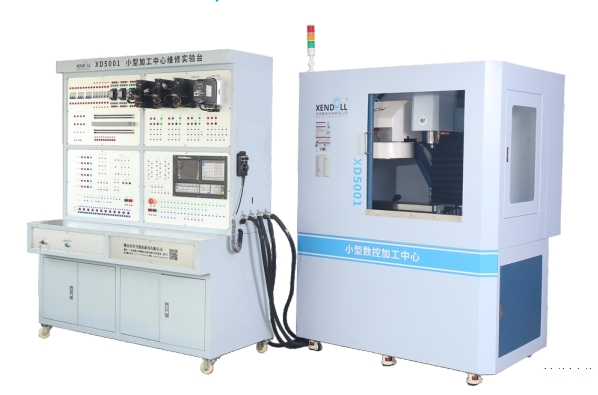

(1). High performance 3 or 5 axis CNC center machine controller.

(2). The standard spec includes electronic hand wheel.

(3). Selection of high -quality casting materials, more compact.

(4). 8-12 tools ATC.ISO20 spindle type, 24000rpm spindle speed.

(5). USB/U dis/RS232COM etc. many kinds of communication mode, to help users achieve different data transmission and software upgrades easily.

(6). Frequency conversion water cooling motor, low noise, high speed and good durability.

(7). Perfect self-diagnosis function, internal and external status real-time display, alarm immediately when abnormal.

(8). Macro variable, macro definition programming, realizing a variety of logical relations. Support macro program with parameters, convenient to the user programming.

(9). DXF+G code template function, converting DXF automatically to G code for processing.

(10). Graphic simulation function: show the graphics of the processing program and the tool path of the actual operation, tool path simulation processing without controlling the operation of the machine, to exam if the preparation process is correct.

(11). Multi interface selection: support multi language interface display, automatic fault alarm. Processing information display, processing time, the number.

(12). Parameter tabular: Input / output address number setting, only need to fill in the corresponding value in the configuration table.

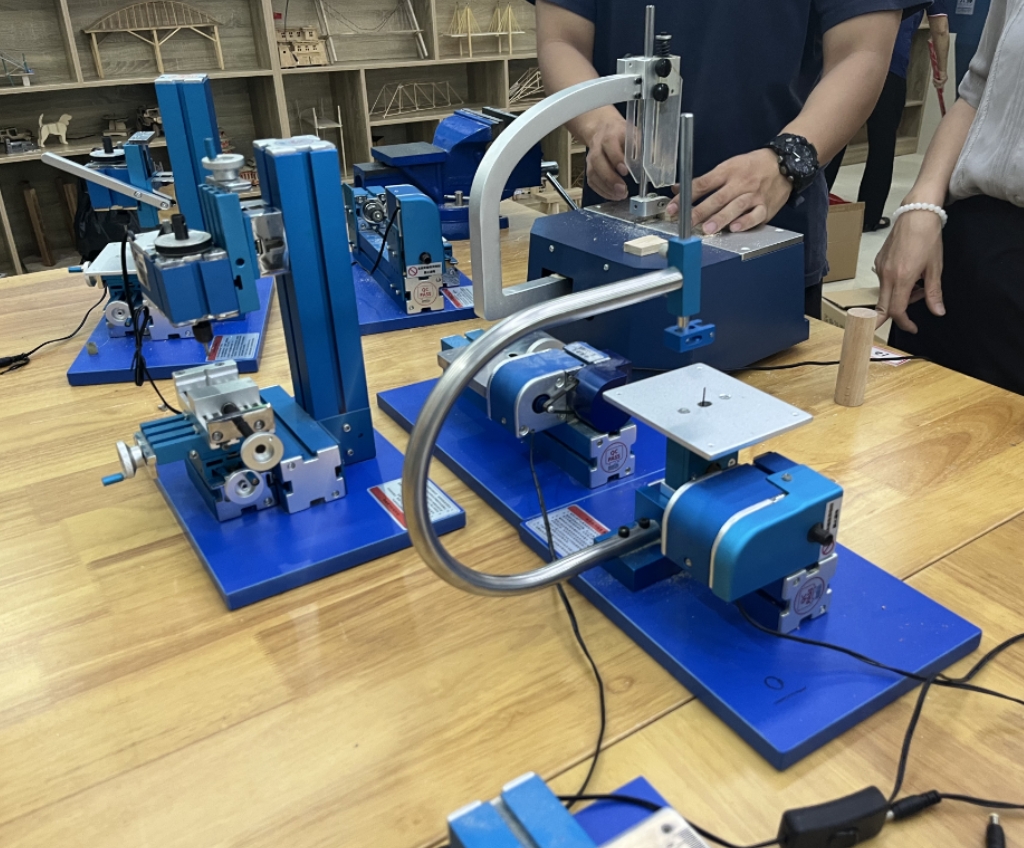

(13). Applicable industry: technology development, advertising design, art, technical college Education & Training CNC and DIY enthusiasts.