Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Apr 30, 2025

Apr 30, 2025

1148

1148

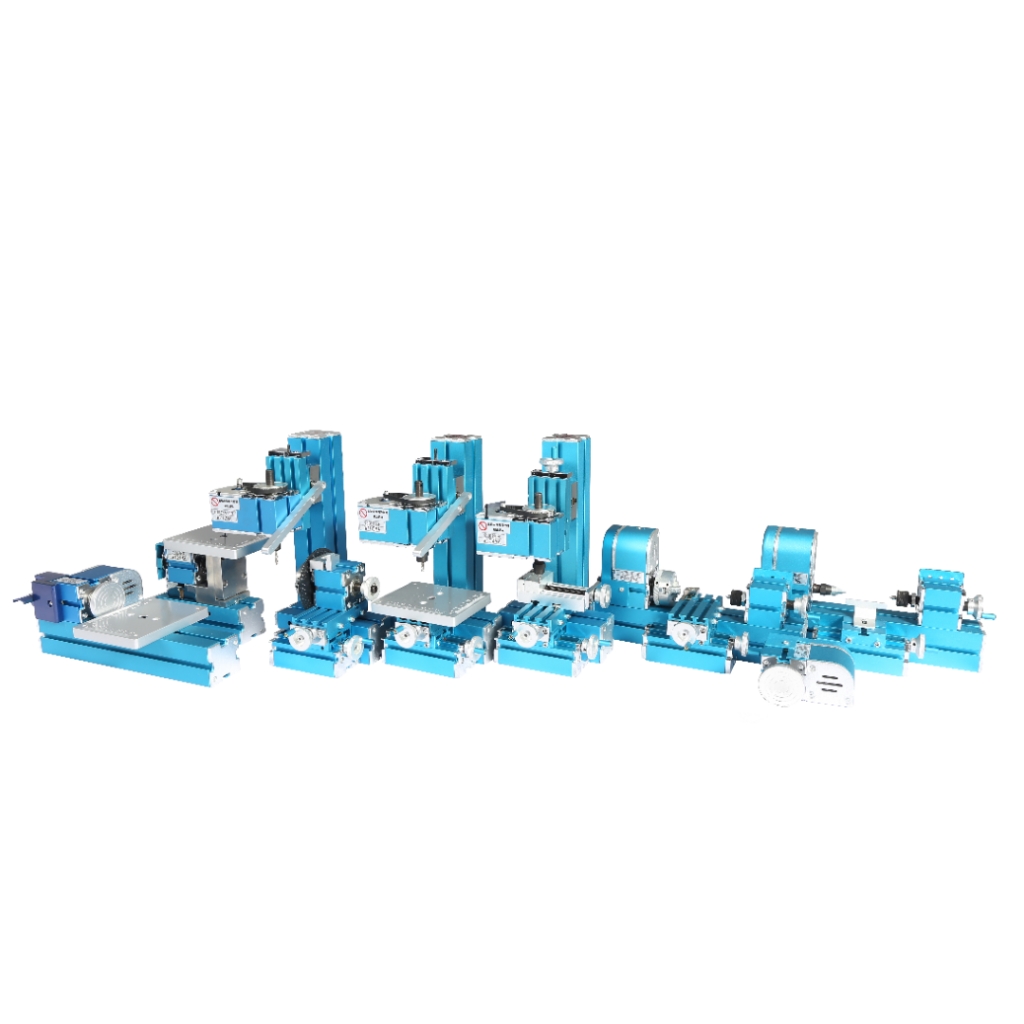

The term "universal machine" might evoke images of futuristic robots or all-in-one gadgets, but in the world of manufacturing and engineering, this title belongs to a humble yet indispensable tool: the lathe machine. For centuries, lathes have been the backbone of workshops, enabling craftsmen and engineers to shape raw materials into precise components. Today, their versatility extends beyond industrial settings, finding a critical role in STEM education through compact, user-friendly versions like mini lathes. But why exactly is the lathe machine called "universal"? And how do mini lathes empower the next generation of innovators? This article explores the lathe’s multifaceted capabilities and its transformative impact on hands-on learning.

The lathe’s reputation as a "universal machine" stems from its unparalleled adaptability across industries and applications. Historically, lathes date back to ancient Egypt, where they were used to carve wood and stone. Over time, their design evolved to handle metals, plastics, and advanced alloys, making them indispensable in manufacturing, aerospace, automotive, and even artisanal crafts.

What makes a lathe "universal"? Unlike specialized machinery designed for a single task (e.g., drilling or milling), a lathe performs multiple operations with minimal reconfiguration. From turning cylindrical shapes to threading, grooving, knurling, and even complex taper cutting, a single lathe machine can replace several tools. This versatility earned it the title of a "universal workshop" in the 19th century, a legacy that continues today.

To understand why lathes are deemed universal, let’s break down their core capabilities:

Turning

The primary function of a lathe is rotating a workpiece against a cutting tool to remove material and create cylindrical shapes. This process, known as turning, is fundamental for producing shafts, bolts, and even decorative spindles.

Facing and Grooving

Lathes can flatten the ends of workpieces (facing) or carve precise grooves for mechanical fittings.

Thread Cutting

By synchronizing the rotation of the workpiece with the movement of the cutting tool, lathes produce accurate screw threads—a critical feature for fasteners and machinery components.

Drilling and Boring

With the right attachments, lathes double as precision drilling machines, creating holes or enlarging existing ones (boring).

Knurling and Tapering

Lathes add textured grips (knurling) or conical shapes (tapering), essential for tools, handles, and custom parts.

This diversity of functions eliminates the need for multiple machines, saving space, cost, and setup time—a key advantage for workshops, hobbyists, and educators alike.

While full-sized industrial lathes dominate factories, mini lathes have emerged as game-changers in educational environments. Compact, affordable, and safe for beginners, these machines are ideal for teaching STEM (Science, Technology, Engineering, and Mathematics) concepts through hands-on projects. Here’s how they foster innovation:

Mini lathes allow students to grasp core principles of mechanical engineering, such as:

Material Properties: Testing how metals, plastics, or woods behave under cutting forces.

Tolerances and Precision: Learning to achieve micrometer-level accuracy in machining.

Kinematics: Observing the relationship between rotational motion, cutting speed, and tool geometry.

From designing custom robot parts to prototyping sustainable energy components, mini lathes empower students to turn abstract ideas into tangible solutions. For instance, a high school team might use a lathe to create wind turbine shafts or gears for a robotics competition.

By mastering mini lathes, students gain early exposure to Computer Numerical Control (CNC) basics, CAD/CAM software integration, and lean manufacturing practices—skills highly valued in industries like aerospace and automation.

Safety and Accessibility

Mini lathes are designed with safety features like emergency stops, lower horsepower motors, and enclosed components, making them suitable for younger users.

Cost-Effectiveness

Schools and hobbyists can acquire mini lathes at a fraction of the cost of industrial models, democratizing access to advanced manufacturing tools.

Space Efficiency

Their compact footprint allows integration into crowded classrooms or home workshops.

Scalability

As students progress, mini lathes can be upgraded with digital readouts, CNC kits, or 3D-printing attachments, aligning with evolving educational needs.

Imagine a STEM program where students are tasked with building a functional clock. Using a mini lathe, they:

Turn brass rods into hour and minute hands.

Cut precise threads for the clock’s winding mechanism.

Engrave numerical markings on the face.

This project integrates geometry, physics, and design thinking, showcasing the lathe’s role as a "universal" teaching tool.

The lathe machine’s title as a "universal machine" is well-deserved. Its ability to perform countless operations with precision and efficiency has cemented its place in workshops worldwide. Now, with the rise of mini lathes for STEM education, this legacy is being redefined. By bringing industrial-grade capabilities into classrooms, mini lathes inspire creativity, teach critical technical skills, and prepare students to tackle real-world engineering challenges. For educators and institutions aiming to equip future innovators, investing in a mini lathe isn’t just about buying a tool—it’s about unlocking limitless possibilities.

For details, please refer to the following link:

https://www.xendolltools.com/category/micro-cnc-machine.html

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options