Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

May 01, 2025

May 01, 2025

1092

1092

The lathe, a machine that has shaped human innovation for millennia, remains a cornerstone of modern manufacturing and education. By rotating materials against cutting tools, lathes create symmetrical, functional, and artistic objects with precision. Today, mini lathes—compact, user-friendly versions of their industrial counterparts—are revolutionizing STEM (Science, Technology, Engineering, and Mathematics) education. Paired with wood plastic, these machines empower students, hobbyists, and professionals alike. This article explores how mini lathes work, their role in STEM learning, and why wood plastic is the ideal material for ducators, overseas machinery dealers, and machining enthusiasts.

A lathe’s primary purpose is to shape materials through rotational motion. Here’s how it works:

Turning: Removing layers from a rotating workpiece to create cylindrical shapes (e.g., table legs, tool handles).

Facing: Flattening the end of a workpiece for precise alignment.

Drilling: Boring holes using tailstock-mounted tools.

Threading: Cutting screw threads for bolts or fittings.

Knurling: Adding grip-enhancing patterns to surfaces.

Mini Lathes: A Modern Twist

Designed for accessibility, mini lathes retain these core functions but are scaled down for safety and affordability. Mini lathes thrive in classrooms and hobbyist spaces, particularly when used with woodplastic—a durable yet lightweight material designed for sustainability, offering the machining simplicity of wood and the ruggedness of plastic.

STEM education thrives on hands-on experimentation. Mini lathes and woodplastic offer unique advantages:

Woodplastic, a child-safe material free of toxins and sharp fragments, is fully recyclable—perfect for fostering hazard-free learning environments in schools.

Unlike metal, it requires less force to machine, reducing risks for beginners.

Science: Study material properties (e.g., how woodplastic reacts to heat or stress).

Engineering: Design functional parts like gears or robotic arms.

Mathematics: Calculate dimensions, angles, and rotational speeds.

Art: Create decorative items, blending technical and creative skills.

Project Example: Students craft woodplastic wind turbine blades, testing aerodynamics and energy efficiency.

Outcome: Teaches renewable energy concepts, precision machining, and sustainable design.

From prototyping to finished products, mini lathes unlock endless STEM possibilities:

Educational Tools: Create lab equipment like test tube holders or microscope parts.

Robotics: Machine lightweight joints or sensor mounts for student-built robots.

Eco-Challenges: Task students with designing woodplastic products like reusable cutlery or modular furniture.

Skills Gained: Lifecycle analysis, material recycling, and eco-design principles.

Sculptural Projects: Combine lathe work with 3D printing to make hybrid sculptures.

Cultural Relevance: Replicate historical artifacts (e.g., wooden gears from ancient machinery) using modern materials.

For overseas machinery dealers and educational distributors, promoting mini lathes and woodplastic aligns with global trends:

Schools and makerspaces worldwide seek affordable, space-saving equipment.

Wood plastic appeals to eco-conscious institutions and governments promoting sustainability.

Bundling mini lathes with woodplastic kits creates a unique selling proposition.

Highlight certifications (e.g., non-toxic, recyclable) to attract buyers in regulated markets.

Provide lesson plans or project templates (e.g., “Build a woodplastic clock mechanism”) to help educators integrate lathes into STEM programs.

To maximize impact, educators and dealers can adopt these strategies:

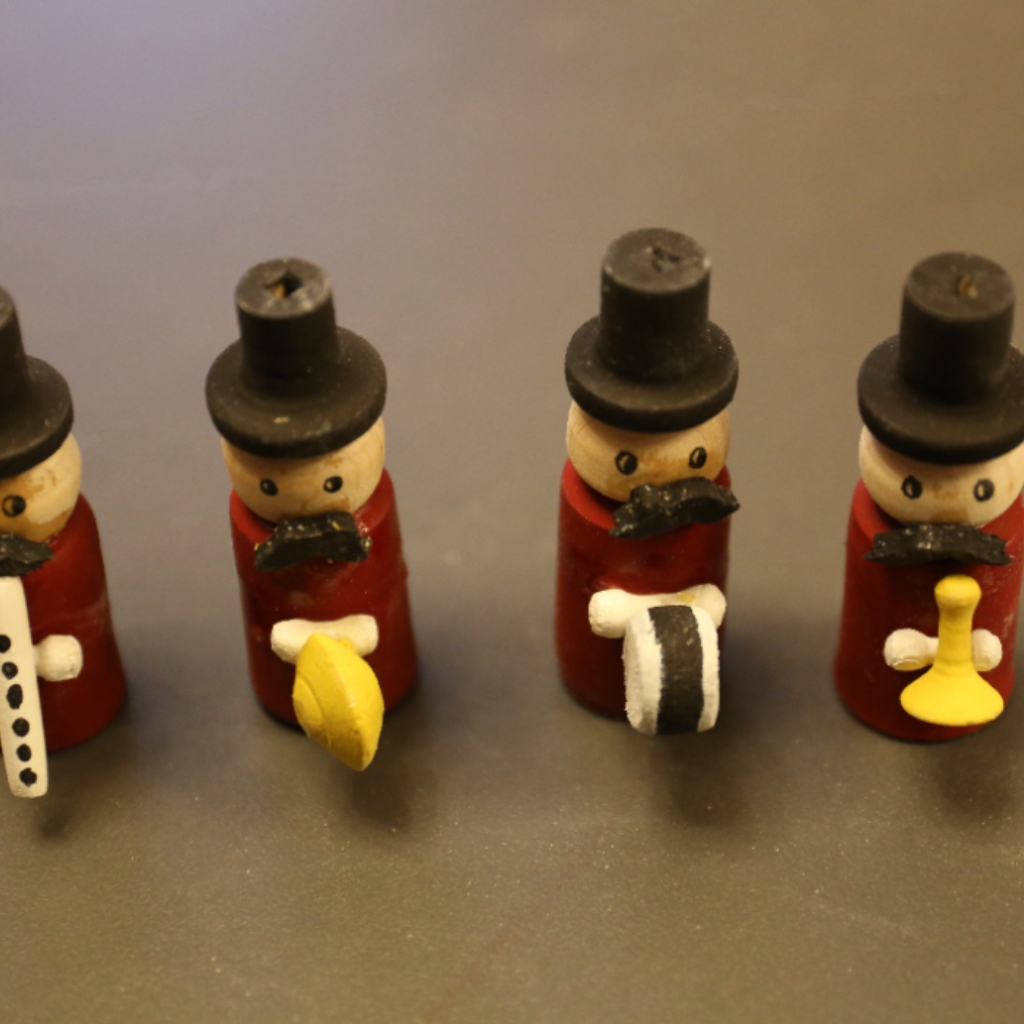

Beginner: Simple projects like wood plastic pens or chess pieces (focus: tool basics).

Intermediate: Functional parts like pulleys or custom screws (focus: precision).

Advanced: Multi-material assemblies, such as woodplastic-aluminum hybrids (focus: engineering systems).

Host “Innovate with Wood plastic” challenges, inviting students to design solutions for local environmental issues.

Partner with overseas machinery dealers to sponsor prizes or global student exchanges.

Collaborate with sustainable material suppliers to offer discounted woodplastic bundles.

Showcase student projects at trade shows to demonstrate real-world applications.

The lathe, once a tool of industrial revolution, is now a gateway to 21st-century STEM education. Mini lathes, combined with woodplastic, democratize access to machining skills while promoting sustainability and creativity. For educators, they provide a platform to teach cross-disciplinary problem-solving; for overseas machinery dealers, they represent a growing market niche at the intersection of education and eco-innovation.

By embracing these tools, we equip future engineers, designers, and inventors with the skills to shape a smarter, greener world—one rotating workpiece at a time.

For details, please refer to the following link:

https://www.xendolltools.com/category/micro-cnc-machine.html

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options