Blog

Xendoll has 22 years of experience in the production of small machine tools. We will help you choose the suitable machine and share our experience in CNC machining with you.

Jun 30, 2025

Jun 30, 2025

1120

1120

For generations, the buzz of a bandsaw, the smell of sawdust, and the feel of shaping metal were staples of the high school experience through Industrial Arts (IA) – commonly known as "shop class." Yet, walking through many modern high schools today, you’re more likely to find rows of computers than drill presses. This significant shift away from teaching foundational hands-on skills raises a critical question: Why have high schools largely stopped teaching Industrial Arts?

The Gradual Fade of the Workshop: Key Reasons

Several interconnected factors have contributed to the decline of traditional Industrial Arts programs:

The Relentless Pressure of Standardized Testing & Academic Focus: The driving force behind much educational policy since the late 20th century has been standardized testing in core academic subjects (math, science, language arts). Funding, school rankings, and even teacher evaluations became heavily tied to performance on these tests. Subjects perceived as non-academic or vocational, like IA, were often the first to face budget cuts or reduced instructional time to make way for more test preparation. The focus shifted decisively towards college preparation, often defined narrowly as academic coursework, overlooking the diverse pathways to successful careers.

Budgetary Squeeze & High Operating Costs: Maintaining a safe, functional IA workshop is expensive. Equipment (lathes, mills, welders, woodworking tools) requires significant capital investment, ongoing maintenance, and costly upgrades. Consumable materials (wood, metal, plastics) add recurring expenses. Compared to equipping a computer lab or a standard classroom, the overhead for IA is substantially higher. When budgets tightened, these high-cost programs were vulnerable targets for elimination or downsizing.

Evolving Safety Concerns & Liability Issues: Operating heavy machinery inherently carries risks. While safety was always paramount in good IA programs, heightened awareness of liability, coupled with sometimes outdated facilities or insufficient teacher training on newer safety protocols, made districts increasingly nervous. The potential for accidents, however small, became a perceived legal and financial risk that some administrators preferred to avoid altogether by closing programs.

The Rise of Technology & Misguided "Relevance": As computers became ubiquitous, there was a push to make curricula "future-proof" and technologically advanced. While well-intentioned, this sometimes led to the mistaken belief that traditional hands-on skills like machining, woodworking, or mechanics were obsolete "old economy" skills. The focus shifted towards digital literacy (important in its own right), often at the expense of tactile, physical making and problem-solving. The concept of "making" became associated purely with coding and 3D printing, overlooking the enduring need for foundational manual skills.

Shifting Career Perceptions & the "College for All" Push: A powerful cultural narrative emerged promoting a four-year college degree as the only path to a successful, respectable career. This unintentionally devalued skilled trades and technical careers, often reinforced by guidance counselors and parents unfamiliar with modern manufacturing and trade opportunities. Industrial Arts, seen as a pathway to these "lesser" vocations, suffered from this perception bias. Students were steered away, reducing enrollment and further justifying program cuts.

The Consequences: More Than Just Lost Skills

The disappearance of IA programs isn't just about nostalgia; it has tangible negative impacts:

The Widening Skills Gap: Industries like advanced manufacturing, construction, and skilled trades are desperately seeking workers. The lack of early exposure to these fields in high school means fewer students discover an aptitude or passion for them, exacerbating critical labor shortages.

Lost Development of Practical Intelligence: IA taught invaluable, transferable skills: spatial reasoning, measurement and precision, problem-solving with physical constraints, understanding materials, sequential planning, tool literacy, and the deep satisfaction of creating a tangible object. These skills foster a different kind of intelligence crucial for innovators, engineers, designers, and entrepreneurs.

Diminished Creative & Tactile Outlets: For many students, shop class was a vital creative outlet and a break from purely abstract learning. It engaged kinesthetic learners and provided a sense of accomplishment unmatched by a high test score. Removing this outlet leaves a gap in holistic education.

Disconnection from the Physical World: We risk raising generations with little understanding of how the physical objects around them are made, repaired, or maintained. This disconnection impacts consumerism, sustainability, and basic self-reliance.

The Path Forward: Revaluing Hands-On Learning

Thankfully, there's a growing recognition of the problem. Movements like Maker Education, STEM/STEAM (adding Arts and Making), and renewed focus on Career and Technical Education (CTE) are attempting to fill the void. However, true revival requires:

Reforming Educational Priorities: Recognizing diverse intelligences and career paths as equally valuable. Integrating hands-on making into STEM, not replacing it.

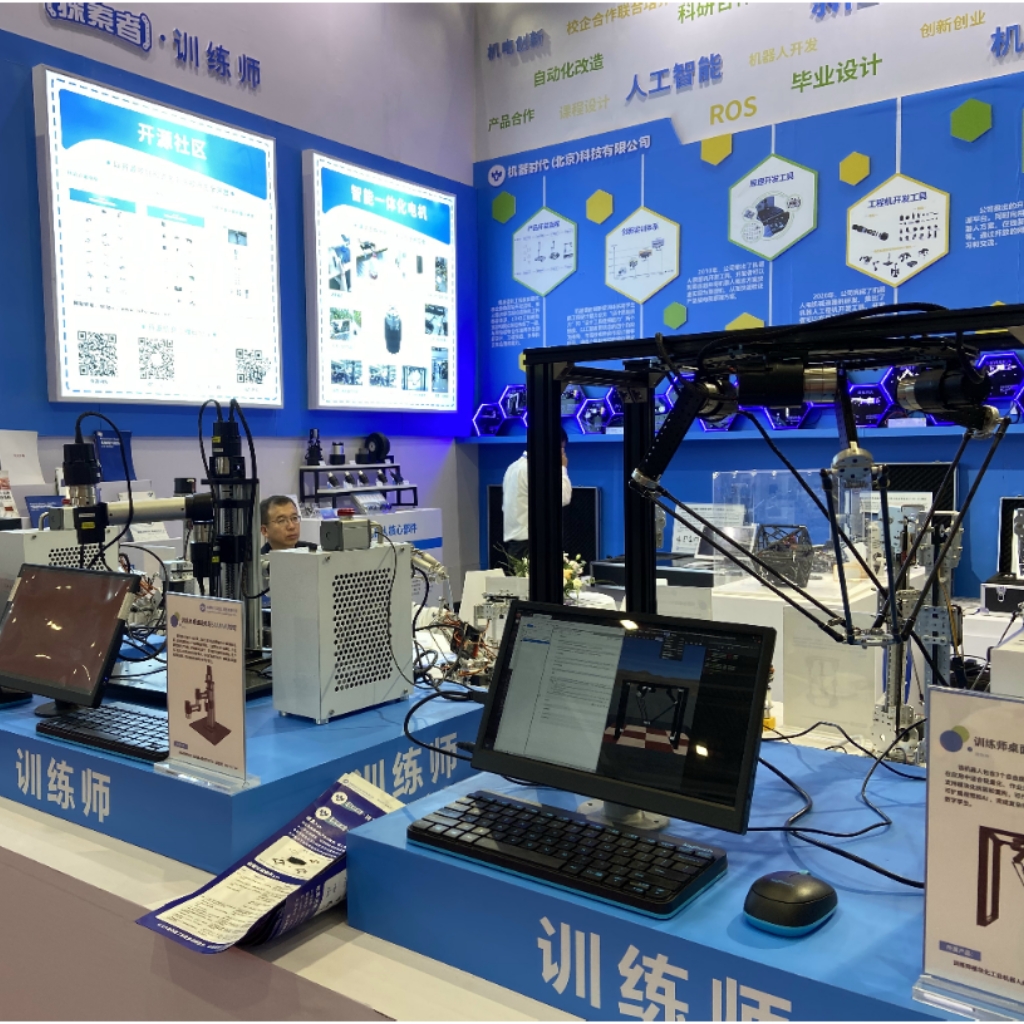

Investment in Modern, Safe Facilities: Updating workshops with safer, more accessible equipment (like miniaturized, benchtop CNC machines, compact lathes, and advanced dust collection) is crucial.

Teacher Training & Recruitment: Developing pathways to train the next generation of Industrial Arts/Technology & Engineering educators.

Community & Industry Partnerships: Connecting schools with local manufacturers and tradespeople to showcase career opportunities and provide resources.

Conclusion: The Essential Need Endures

High schools stopped teaching traditional Industrial Arts due to a complex mix of budget pressures, shifting academic priorities, misplaced notions of relevance, safety concerns, and cultural biases against skilled trades. However, the fundamental human need to understand, shape, and create in the physical world has not disappeared. The skills fostered in the workshop – critical thinking, problem-solving, craftsmanship, and material understanding – are timeless and increasingly valuable in our technology-driven world.

Platforms like XendollTools.com recognize this enduring need. By providing high-quality, accessible mini machine tools, compact workshop equipment, and precise accessories, we empower overseas mechanical distributors, educational equipment resellers, and individual machining enthusiasts worldwide. These tools make it possible for schools to reintroduce safe, space-efficient hands-on learning, for educators to inspire the next generation of makers and engineers, and for hobbyists to discover the profound satisfaction of building and creating. The workshop might have faded from many schools, but the spirit of making and the demand for the skills it teaches are stronger than ever – and the tools are now more accessible than before to reignite that essential spark.

For details, please refer to the following link:https://www.xendolltools.com/category/micro-cnc-machine.html

Show all our samples

Show all our samples

Provide you with a free quote

Provide you with a free quote

Answer all the questions you may have

Answer all the questions you may have

Guided installation and other options

Guided installation and other options